Temperature data logger

The Omega OM-21 single-use cold chain temperature data logger monitors the transportation of food products. Placed in shipping containers or packages, it creates a time-based history of the conditions in transit.

The Omega OM-21 single-use cold chain temperature data logger monitors the transportation of food products. Placed in shipping containers or packages, it creates a time-based history of the conditions in transit. The unit is completely user programmable including sampling interval, start delay, temperature units, alarm range and user name. Upon the completion of data logging, the unit automatically generates a PDF report containing data summary, graph and tabular results.

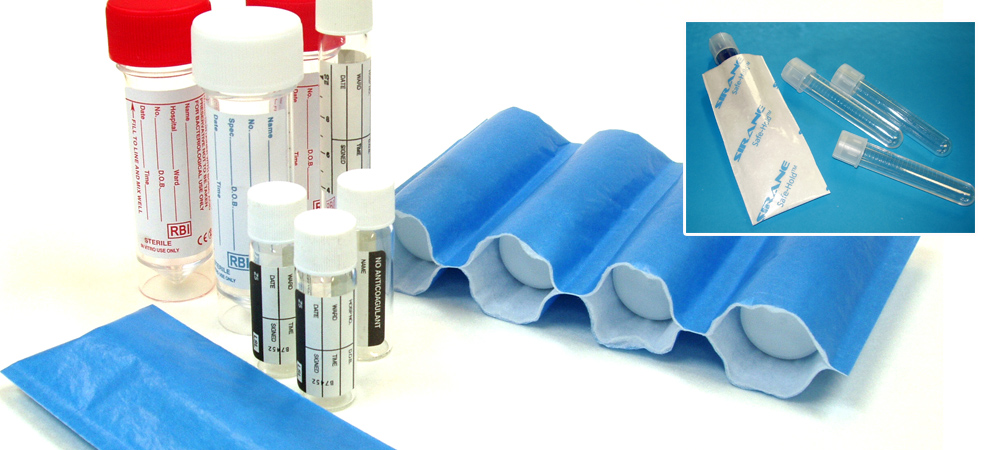

Absorbent Pouches

Absorbent pads and pouches are designed to ensure safe and compliant storage

Owen Mumford launches new touch activated lancet

Owen Mumford, a leading medical device manufacturer, today unveils a new addition to its range of medical devices, available initially in the US before expanding out to other markets. Presented for the first time at the International Diabetes Federation World Diabetes Congress in Vancouver, booth 1403, Unistik® Touch is a touch activated lancet that features Owen Mumford’s unique Comfort Zone Technology®.

Owen Mumford, a leading medical device manufacturer, today unveils a new addition to its range of medical devices, available initially in the US before expanding out to other markets. Presented for the first time at the International Diabetes Federation World Diabetes Congress in Vancouver, booth 1403, Unistik® Touch is a touch activated lancet that features Owen Mumford’s unique Comfort Zone Technology®.

Designed with the end-user in mind, the Unistik® Touch features a touch activated lancet making it intuitive and easy to use. Tania Mackenzie, Senior Global Product Manager at Owen Mumford comments further on Unistik® Touch, “Unistik® Touch is our first touch activated lancet, which is built on our already trusted platform, Unistik®3 device. Unistik® Touch has been created specifically with the end-user’s needs in mind. Being touch activated means there are fewer steps for the end-user to make when sampling blood and with the addition of our Comfort Zone Technology®, is designed for a more gentle experience (1)”.

Mackenzie continues, “The entire Unistik® range is concerned with putting comfort first. Available in 18 gauge, 21 gauge, 23 gauge, 28 gauge and 30 gauge, the introduction of Unistik® Touch allows healthcare providers to have a selection of devices”.

Owen Mumford’s unique Comfort Zone Technology® provides a more comfortable blood sampling experience. It features a series of eight raised dots on the end of the lancet which, when pressed against the sample area, reduces the sensation of pain from the needle piercing the patient’s skin (2).

Research conducted through end-user trials showed that Comfort Zone Technology® reduced the pain experienced during the blood sampling procedure when compared to other devices without the same technology (1).

Unistik® Touch is currently available in the US and is set to be available for the rest of the world later in 2016. For more information on Unistik® Touch visit Owen Mumford during IDF at booth 1403. IDF is a global show, covering all markets, and is the perfect platform to raise awareness of Unistik® Touch ahead of the full market roll out.

References:

Dewland P, Edwards C. A single-blind, randomised, 8-way crossover study to compare the blood volume and pain perception of capillary blood sampling. March 2007.

Gate Theory. Mezack R, Wall PD. The challenge of pain. Penguin, Harmondsworth. 1982 p233

Eye catchy triangular box

Award winning triangular box packaging.

Mondi and Spotless Tea Bag tackle messy problem

The Steabag solution will be presented for the first time at the Mondi booth at Packaging Innovations 2016, 24-25 of February 2016.

In January Mondi signed a manufacturing and sales agreement with Spotless Tea Bag for Steabag, an innovative single portion stand up pouch concept for tea bags. The patented Steabag, invented by Matti Koskinen, captivates by its practical usage and is sustainable as well as compostable.

In January Mondi signed a manufacturing and sales agreement with Spotless Tea Bag for Steabag, an innovative single portion stand up pouch concept for tea bags. The patented Steabag, invented by Matti Koskinen, captivates by its practical usage and is sustainable as well as compostable.

The development combined the material competence and technologies from Mondi Extrusion Coatings with state of the art conversion and pouch making capabilities of Mondi Consumer Goods Packaging. This led, by the end of January, to an exclusive cooperation agreement between Spotless Tea Bag and Mondi comprising the manufacturing within Europe.

“I couldn’t be more impressed on the positive, open-minded attitude and professional expertise Mondi has brought to the concept’s development process,” said Matti Koskinen, inventor of Steabag and the founder of Spotless Tea Bag. “Now with a novel packaging, tea lovers all over the world can make their teatime delightfully spotless.”

The Steabag is the paper based single portion stand up pouch with good barrier properties against oxygen and moisture. It has an aroma barrier, which guarantees keeping the product in good condition till it is used. Additionally it is watertight, so you can place a used tea bag back in the pouch avoiding mess or use of additional dishes.

Using Mondi’s unique biodegradable high barrier material Sustainex, allowing it to be disposed in an environmentally friendly way (both paper & coating are biodegradable according to EN 13432).

“Developing an optimal packaging solution for Steabag confirms Mondi`s capacity to offer smart packaging solutions, tailor-made to our customers need,” commented Thomas Gröner, head of innovation and R&D consumer goods packaging. “We combined a creative concept with our in-depth material and packaging skills – and on top with our commitment to sustainable innovations.”