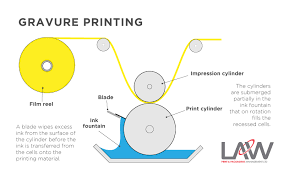

Gravure is an intaglio process, in that the printing image is in recessed form. The printing image consists of recessed cells engraved in a metal image cylinder. This image cylinder runs in an ink duct containing low viscosity liquid ink. The cells and the surface of the cylinder are consequently flooded with ink. A metal doctor blade held against the rotating cylinder then scrapes the surplus ink from the non-image surface of the cylinder. The printing substrate, usually in continuous (web) form, is held against the cylinder by an impression roller so that transfer of the ink takes place. The printed substrate then passes through a heated drying oven so that the solvent is removed by evaporation. Engraving the image cells into the image cylinder is an exacting and expensive process. Originally exposing a photosensitive resist through a positive, developing, and etching the cells into the exposed copper surface by chemical means achieved this. Recent developments use digitally controlled styli to engrave the cells, result in a fast, accurate and less expensive process. The cells, which form the image, are arranged in a regular grid, typically 60 lines per centimeter. This produces cells of about 125μ across. Colour density is proportional to the volume of ink deposit; this is effected by varying the cell volume in one of two ways. Either by controlling the cell depth in cells of equal area, or varying the cell area in cells of equal depth The inks used in gravure are low viscosity dispersions of pigment and binders in solvents.

Caution: The information given above has been taken from different sources and compiled just for giving the readers a better understanding of the process.