There are several sealing techniques used in packaging to ensure the integrity, safety, and freshness of various products. Following is the list of some of the different sealing techniques:

1. Heat Sealing: Heat sealing is one of the most widely used sealing methods. To heat seal a package, heat is applied to a thermoplastic material, such as polyethylene or polypropylene, to create a bond between two surfaces. Heat sealing can be achieved through equipment like heat sealers, impulse sealers, or continuous band sealers.

1. Heat Sealing: Heat sealing is one of the most widely used sealing methods. To heat seal a package, heat is applied to a thermoplastic material, such as polyethylene or polypropylene, to create a bond between two surfaces. Heat sealing can be achieved through equipment like heat sealers, impulse sealers, or continuous band sealers.

2. Adhesive Sealing: Adhesive sealing makes use of adhesive materials to bond two surfaces together. It typically requires applying a liquid or hot melt adhesive onto one surface and then pressing the two surfaces together to create a secure seal. Adhesive sealing is most commonly employed for flexible packaging materials like pouches or bags.

2. Adhesive Sealing: Adhesive sealing makes use of adhesive materials to bond two surfaces together. It typically requires applying a liquid or hot melt adhesive onto one surface and then pressing the two surfaces together to create a secure seal. Adhesive sealing is most commonly employed for flexible packaging materials like pouches or bags.

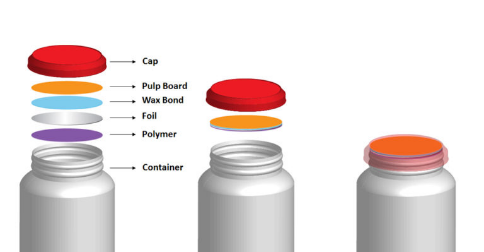

3. Induction Sealing: Induction sealing is used for sealing containers with foil or induction-sealing liners. An electromagnetic induction is used to heat a foil liner, which melts a polymer layer and creates an airtight seal when pressed against the container's rim. This method is often used for sealing bottles, jars, or other containers for products like pharmaceuticals, food, or beverages.

3. Induction Sealing: Induction sealing is used for sealing containers with foil or induction-sealing liners. An electromagnetic induction is used to heat a foil liner, which melts a polymer layer and creates an airtight seal when pressed against the container's rim. This method is often used for sealing bottles, jars, or other containers for products like pharmaceuticals, food, or beverages.

4. Ultrasonic Sealing: Ultrasonic sealing uses high-frequency ultrasonic vibrations to create frictional heat at the interface of two materials, causing them to melt and fuse together. This technique is also used to seal thermoplastic films or blister packs and is known for its speed and precision.

4. Ultrasonic Sealing: Ultrasonic sealing uses high-frequency ultrasonic vibrations to create frictional heat at the interface of two materials, causing them to melt and fuse together. This technique is also used to seal thermoplastic films or blister packs and is known for its speed and precision.

5. Vacuum Sealing: Vacuum sealing involves removing air from a package or container before sealing it. It requires a vacuum sealing machine that sucks out the air, creating a tight seal. Vacuum sealing is most often used for food packaging to extend the shelf life and maintain product freshness.

5. Vacuum Sealing: Vacuum sealing involves removing air from a package or container before sealing it. It requires a vacuum sealing machine that sucks out the air, creating a tight seal. Vacuum sealing is most often used for food packaging to extend the shelf life and maintain product freshness.

6. Pressure Sensitive Sealing: Pressure sensitive sealing relies on the use of pressure-sensitive adhesives (PSAs) that adhere to the surfaces upon applying pressure. This method is commonly seen in self-sealing bags or envelopes, where the adhesive is pre-applied to one surface, and pressure is applied to create a bond.

6. Pressure Sensitive Sealing: Pressure sensitive sealing relies on the use of pressure-sensitive adhesives (PSAs) that adhere to the surfaces upon applying pressure. This method is commonly seen in self-sealing bags or envelopes, where the adhesive is pre-applied to one surface, and pressure is applied to create a bond.

7. Zipper Sealing: Zipper seals simply interlock plastic zippers or tracks in a reversible format that allows for repeated opening and closing of the package. It is most effective for resealable bags or pouches, providing convenient access to the contents while maintaining freshness.

The choice of sealing method depends on factors such as the type of product, packaging material, required level of protection, and production requirements.