Top 3D Printers

Top 3D Printers Revolutionizing Packaging in 2024

In 2024, 3D printers have become key tools for companies seeking to innovate, reduce waste, and improve sustainability in packaging. Here's a look at the top 5 3D printers making waves in the packaging world.

1. Ultimaker S5 Pro Bundle

Best for: Small-scale, high-quality packaging prototypes

The Ultimaker S5 Pro Bundle is widely praised for its versatility and precision. Combining dual extrusion with a wide range of material compatibility, this printer excels at producing detailed prototypes and customized packaging designs. The S5 Pro also includes an Air Manager and Material Station, which improves reliability and ensures safe printing of materials like PLA, ABS, and TPU—ideal for eco-friendly packaging options.

- Key Features:

- Dual extrusion for multi-material printing

- Compatibility with a wide range of filaments, including bio-based materials

- Enhanced reliability with filament drying and automatic material switching

- Intuitive software for easy design integration

For companies focused on sustainable and creative designs, the Ultimaker S5 Pro is a solid investment. Its eco-friendly options and precision make it ideal for creating custom, high-end packaging.

2. Formlabs Form 3L

Best for: Large-scale, intricate packaging prototypes

The Form 3L is a large-format resin printer from Formlabs, known for producing highly detailed and smooth parts. This is particularly useful for packaging design, where aesthetics and intricate features are crucial. The SLA (Stereolithography) technology used in the Form 3L ensures that fine details, such as embossed logos or complex textures, are accurately reproduced.

- Key Features:

- Large build volume (33.5 x 20 x 30 cm) for creating bigger prototypes or multiple parts in one run

- Industry-leading resolution and surface finish

- Material versatility, including flexible and rigid resins

- Automated resin dispensing for seamless production

The Form 3L allows companies to explore complex designs while minimizing the need for post-processing, which speeds up the product development cycle.

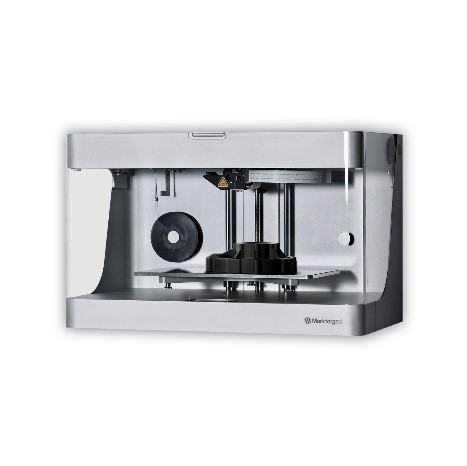

3. Markforged Mark Two

Best for: Durable, functional packaging components

Markforged’s Mark Two stands out by incorporating continuous carbon fiber into 3D-printed parts, significantly increasing strength without sacrificing flexibility. This makes it ideal for packaging companies that require durable components, such as molds or fixtures used in the packaging process.

- Key Features:

- Continuous carbon fiber reinforcement for enhanced strength

- Wide range of industrial-grade materials, including Onyx and Nylon

- Integrated cloud-based software for remote printing and monitoring

- High dimensional accuracy, critical for functional parts

While the Mark Two may not be geared towards aesthetic packaging prototypes, its ability to create robust parts and tools used in packaging production is unmatched.

4. Prusa i3 MK4

Best for: Affordable, rapid prototyping

Prusa 3D printers have garnered a reputation for being highly affordable without compromising on quality. The Prusa i3 MK4 continues this trend, offering impressive print resolution and reliability at a price point accessible to smaller businesses. It’s an excellent choice for rapid prototyping, allowing teams to iterate quickly on packaging designs without breaking the bank.

- Key Features:

- Modular design with easy upgrades and repairs

- High-resolution prints with consistent layer adhesion

- Multi-material upgrade kit available for mixed-material designs

- Open-source software and hardware for customization

The Prusa i3 MK4 is an excellent option for startups and smaller companies looking to innovate in packaging without large upfront investments.

5. HP Jet Fusion 5200 Series

Best for: High-volume, production-level packaging solutions

HP’s Jet Fusion 5200 series is a game-changer for companies ready to scale. Utilizing Multi Jet Fusion (MJF) technology, this 3D printer excels in producing parts quickly, making it ideal for packaging companies that need both high-volume output and precision. The printer can manufacture packaging components or even end-use packaging materials, providing a production-ready solution with minimal lead time.

- Key Features:

- High-speed, large-scale production capabilities

- Consistent mechanical properties across parts

- Industry-grade accuracy, perfect for tight tolerances in packaging components

- Low running costs due to efficient material usage

For large-scale manufacturers looking to integrate 3D printing into their packaging line, the HP Jet Fusion 5200 offers a scalable, cost-effective solution.

Other options:

Stratasys F370

The Stratasys F370 is a versatile 3D printer that supports a wide range of materials, including engineering-grade thermoplastics. This flexibility allows for the creation of packaging solutions with specific properties, such as durability, heat resistance, or chemical resistance.

Carbon DLS Technology

Carbon's Digital Light Synthesis (DLS) technology offers a unique approach to 3D printing, enabling the production of complex, high-resolution parts in a fraction of the time. This technology is particularly well-suited for creating intricate packaging designs with smooth surfaces and fine details.

Nexa3D NXE 400

The Nexa3D NXE 400 is a high-speed 3D printer that offers exceptional throughput and accuracy. It is designed for rapid prototyping and low-volume production of packaging components, allowing for quick iterations and efficient product development.