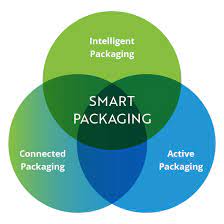

In today's scenario, you hear a lot about these terms - Smart Packaging, Intelligent Packaging, Active Packaging & connected Packaging. So let's dive into these terms and how these packaging benefited consumers and Brands using this technology.

- Smart Packaging: Smart packaging” is an umbrella term that describes packaging that uses technology to do things that go beyond just covering a product. Smart packaging is usually embedded with technology that can sense or provide information about the product or brand. Smart packaging describes a large category of packaging that leverages technology to provide functionality that goes beyond simply housing a product.

- Intelligent Packaging: Intelligent packaging” is one type of smart packaging that’s typically used for food, beverage, and pharmaceutical products. Intelligent packaging may include sensors that can detect the freshness or temperature of the package contents. Freshness or time/temperature indicators or sensors can be integrated inside or outside the packaging to show retailers and customers if an important limit has been exceeded.

For example, In the packaging could indicate bacterial growth, leaky packaging, or temperature disruption would notice by the color change, In the pharmaceutical industry, intelligent drug packaging with built-in RFID chips, LEDs, and tiny loudspeakers can register the removal of pills and sound an alarm if they are taken incorrectly. Medication packaged with NFC chips allows customers to read package inserts and reorder medication using a smartphone.

-

Active Packaging: Active packaging” goes a step further than intelligent packaging to allow the package to interact with its contents in order to improve product shelf life or the quality of the contents during storage. It is also popular in Food & beverage Industry. Light-filtering materials, oxygen and ethylene absorbers, antimicrobial surface coatings, and moisture-regulating materials can be integrated into the packaging or added separately as an insert.

For example, active packaging may release antimicrobial agents to prevent bacterial growth when it senses that a product’s freshness is being compromised. Some beers packaged in plastic bottles contain oxygen absorbers in the screw caps that can extend the beer’s shelf life from three to six months. Film packaging with ethylene absorbers can absorb the ripening hormone ethylene while the food is being stored to ensure a longer shelf life.

-

Connected Packaging: Connected packaging isn’t limited to food and beverage products—it has applications in almost every retail product category, including toys, cosmetics, gaming, and apparel. In connected packaging applications, a connected device is attached or a special code is mentioned, which with Bluetooth or scan helps to consumers to get the information or the data.

-

For example, Mallya automatically captures injection data (dose, date, and time) and sends the information in real-time to a mobile app thanks to Bluetooth technology. Moreover, the reported information is guaranteed with a high level of reliability.

Connected packaging applications are gaining popularity with marketers due to their ability to create deeper relationships with customers to elevate brand loyalty and increase customer lifetime value.