We’ve already covered two primary categories of adhesives; hot melts and water-based adhesives, in the last blog. Now we move on to solvent-based and pressure-sensitive adhesives and their applications.

Solvent-based adhesives are mixtures of solvents and thermoplastic or slightly crosslinked polymers. These include polychloroprene, polyurethane, acrylic, silicone, and natural and synthetic rubbers (elastomers). They contain significant amounts of volatile organic compounds (VOCs), which are considered harmful and irritants. Thus, this category of adhesives is subject to regulations worldwide.

Application

They can be applied by roller, brush, and spray or as beads either manually or by automated machines. They typically gain bond strength when dried and, in some cases when cured.

Features

• Less sensitive than other types of adhesives to contaminants like grease and oil on the substrate to be bonded due to formulation with organic solvents

The solvent-based adhesive can be classified as either wet or dry bonding.

With Wet-bonding adhesives the substrates must be bonded while the adhesive is still liquid, after application of the adhesive.

However, allowing some time to pass for evaporation to occur prior to the set time will increase the initial strength of the adhesive bond and it will also allow for quicker assembly. Full bond strength is obtained after the remaining solvent is fully evaporated or absorbed by the substrate which requires at least one substrate to be porous.

In dry bonding, also known as contact adhesives, both substrates are coated with adhesive and the solvent is allowed to evaporate before the parts are bonded. The parts are then mated using only light pressure to insure adequate contact of the two adhesive films. The full bond strength only builds over time as the polymers of the two adhesive films co-mingle.

Wet vs. Dry Bonding

Contact adhesives have usually much higher initial green strength and also offer higher final strength, especially when heat-cured.

They also have better heat and creep resistance than wet-bonded adhesives.

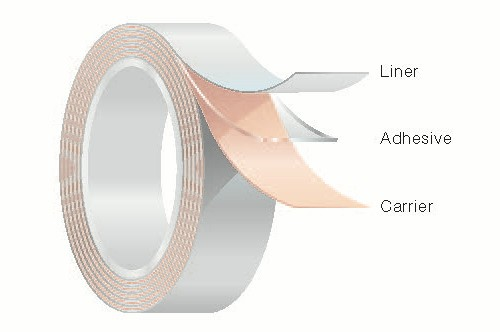

Pressure sensitive adhesives (PSA) are usually applied as tape; it can be a material that will hold two surfaces together solely by surface contact. The bond strength is directly proportional to the pressure applied during application.

Application

Pressure sensitive adhesives can be used as replacement to screws, rivets, nuts and bolts and clips.

Features

PSAs are usually able to bond with a varied selection of materials including cloth, paper, plastic, metal, wood and glass.

It is a dry solid that does not require activation in the form of a solvent, water or heat at the time of application; they have a permanent level of tack at room temperature.

Natural tree gums were one of the first materials to be used as a pressure-sensitive adhesive. Today, most common pressure-sensitive polymers employed for PSAs include acrylic, rubbers (elastomers) and silicone.