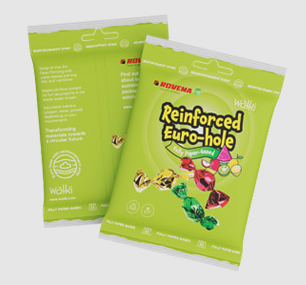

Walki is leading the charge in sustainable packaging solutions with its groundbreaking new concept for euro-hole pouches. Traditionally, sweets and confectionery have been packaged in plastic pouches equipped with euro holes for hanging in supermarkets. However, concerns over plastic waste and environmental impact have prompted the search for alternative materials.

Enter Walki's innovative solution: a reinforced euro-hole pouch concept entirely made from fiber-based materials. Designed to withstand the weight of the contents without tearing at the hole punching, this new concept eliminates the need for plastic film while maintaining structural integrity.

Andreas Rothschink, Head of Product Development and Technical Service at Walki Group, highlights the significance of this innovation: "The transition from film to paper has been hindered by concerns over pouch durability. Our Walki@Seal REH concept addresses this challenge by incorporating an extra strip above the euro hole, ensuring the pouch remains sturdy and reliable."

This breakthrough not only enables confectionery brand owners to make the switch to sustainable packaging but also offers versatility beyond the food industry. From home hardware materials to toys, the fiber-based pouch can cater to a wide range of applications.

Furthermore, the environmental benefits are significant. As the pouch is made from paper, it is fully recyclable within the paper stream, contributing to a circular economy and reducing plastic pollution.

This innovative concept is the result of collaboration between Walki and packaging machine producer Rovema, showcasing the power of partnership in driving sustainable innovation forward. With Walki's fiber-based euro-hole pouch, the future of packaging is both eco-friendly and efficient.