Parcel Health, a leading manufacturer of eco-friendly medication packaging, has unveiled its latest innovation for packaging prescription drugs at pharmacies. The Tully Tube replaces the standard pill bottle with an inventive design that minimizes the use of plastic. Research shows that only a very small percentage of plastic pill bottles are ever recycled. But by switching to the Tully Tube, pharmacies can cut their use of plastic by 53% and, thus, reduce carbon emissions by 30%.

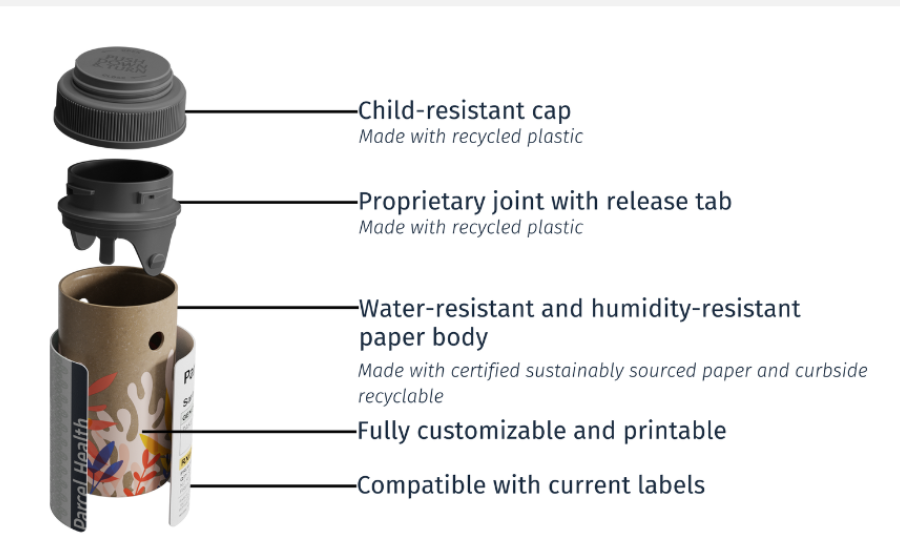

The base of the Tully Tube is made from sustainably sourced and curbside-recyclable paper, while the neck and child-resistant cap is made from recycled plastic. The key breakthrough of this design is that it allows end-users to separate the cap from the paper tube using a proprietary joint fitted with a release tab. Users can then discard the cap and joint with other plastic recyclables. The paper body can be either recycled or composted.

“We’re very excited to launch the Tully Tube. This has been an innovation in the making for many months and it required precise engineering, sustainable material sourcing, and efficient product design. We’re very proud to bring this product to market at a competitive price,” said Mallory Barrett, co-founder and President of Parcel Health.

The Tully Tube is compatible with pharmacy automation units and gives high-volume pharmacies a new option to integrate sustainable packaging into their workflow. The Tully Tube is child-, water- and humidity-resistant. It is also compatible with the labels that pharmacies currently use.

Parcel Health created the Tully Tube as a complement to its fully paper-based pill packaging, the Phill Box. Like the Phill Box, the Tully Tube is fully customizable and printable to align with pharmacies’ unique brands.