Vials for deep-cold drug applications and complex cold-chain requirements

Covid and the subsequent rise of mRNA vaccines brought new types of therapies to the market that require storage at deep-cold temperatures down to -80 °C.

Combined with potentially multiple freeze-thaw cycles, the stress on the glass at these low temperatures increases the chance of vial breakage, especially if the containers are pre-flawed. The risk of breakage is extremely important to pharmaceutical companies since the drugs contained in these vials can cost hundreds, if not thousands of dollars.

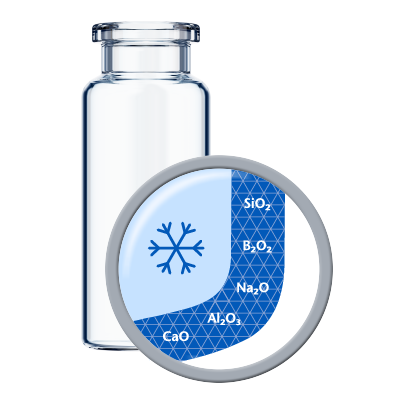

The solution to this challenge is EVERIC® freeze, a glass vial with improved strength for deep-cold storage.

EVERIC® freeze is the ideal container for storing sensitive molecules that require deep-cold storage to keep the drug stable until the point of use. Applications range from mRNA and DNA vaccines to viral vector and gene therapies.

EVERIC® freeze delivers improved strength for deep-cold storage applications down to -80 °C, reducing the risk of breakage. This is based on:

- The use of FIOLAX® OS (Optimized Strength): glass tubing with an improved scratch and fissure specification, without any change in chemical composition.

- An optimized converting process: improved hot forming ensures tighter tolerances.

- A thicker wall: improves resistance to internal pressure while keeping the outer dimensions within ISO tolerances.

- A dedicated inspection: 100% bottom inspection based on the latest inspection technology.

- Flawless process: glass-to-glass contact-free handling.

A reliable drug container for cold-chain requirements

- Manufactured with FIOLAX® OS, an improved-strength tubing with unchanged glass composition

- Optimized vial geometry with tighter dimensional tolerances

- 100% bottom inspection, glass-to-glass free handling, and tighter specification for increased strength

- Possible combination with EVERIC® smooth, an outer silicone coating that ensures a low-friction surface

- Available in a range of formats, from 2-30 ml

EVERIC® freeze vials are available upon request in the adaptiQ® format, a pre-washed and pre-sterilized ready-to-use (RTU) configuration in highly standardized secondary packaging.

Small batches of patient-facing medications and high-value pharmaceuticals often present challenges for fill-and-finish operations. Not only do they require higher quality containers, but they also require more flexibility, with frequent switching between different medications to avoid costly waste.

adaptiQ® vials can be processed on a variety of new and existing fill-and-finish lines, keeping vials nested throughout the process, including freeze-drying.