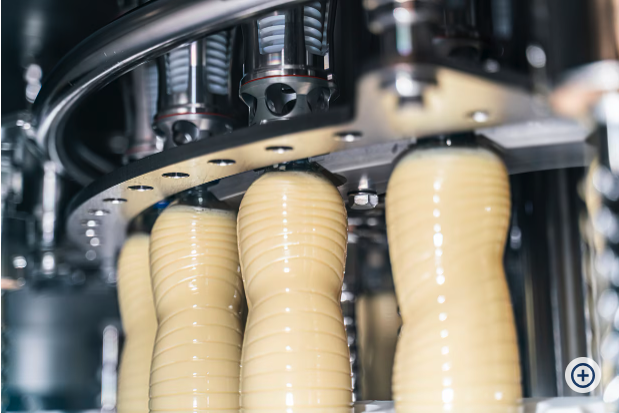

FrieslandCampina, one of the world’s largest dairy cooperatives, is enhancing its production capabilities at its Aalter plant in Belgium by installing a third PET filling line using Krones' dry-aseptic technology. Following the success of their first two lines, Line 1 installed in 2014 and Line 2 in 2020, the cooperative has opted once again for the Contipure AseptBloc DN for its new Line 3.

Line 3 is rated at 24,000 containers per hour for 1.0-liter bottles and will primarily fill liquid cream and other dairy products. Notably, FrieslandCampina will use this line to fill Extended Shelf Life (ESL) milk into PET containers for the first time.

The new line offers flexible packaging options, with two dry-end alternatives: the Variopac Pro WTS for wrap-around cartons, and the Variopac Pro FS for shrink packs along with the Variopac Pro TFS for tray-based shrink packs.

Brecht Deleu, who was involved with the implementation of the first Krones aseptic line and served as a project manager for the second, emphasized the logic behind continuing with the proven technology: "After our positive experience with the first two Contipure AseptBloc DN lines, it was only a logical decision that we would continue to rely on this technology.”

To accommodate Line 3, FrieslandCampina is constructing a new building adjacent to the existing filling hall. Once operational, the new PET line will replace three existing HDPE filling lines, covering most of their capacity and providing space for future expansion.