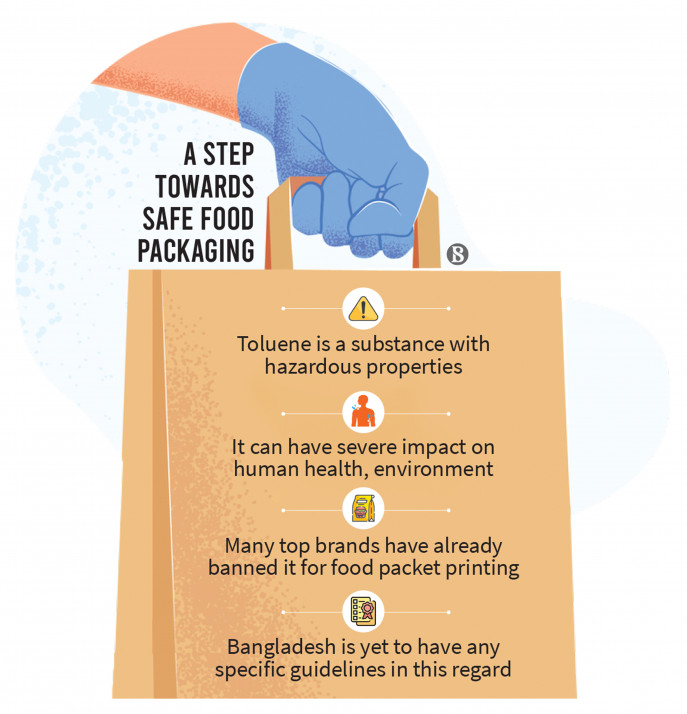

- Toluene is a substance with hazardous properties

- It can have severe impact on human health, environment

- Many top brands have already banned it for food packet printing

- Bangladesh is yet to have any specific guidelines in this regard

Brightly coloured designs of food packets help establish consumer confidence, brand images and promote sales by catching the eye of consumers as they browse along supermarket aisles.

But the packaging and wraps – which is meant for better food safety and product genuineness – might have used printing ink with solvent toluene, which according to European Union regulations, is hazardous to human health. The chemical for printing food packets is banned in India and China, while Sri Lanka voluntarily stopped using it.

Though Bangladesh is yet to have any specific guidelines regarding the topic, Siegwerk – one of the leading global ink and coating manufacturers – offers toluene-free safe food packaging inks to local businesses.

With a $3.45 million investment, Siegwerk opened its blending centre in the Meghna Economic Zone in 2021. The ink-maker says it has developed a solid customer base that includes Nestle, Unilever, Arla Foods (Dano), Perfetti Van Melle and Pran.

Siegwerk has over 190-year history in tailored ink technology and services. The company is now serving customers in more than 100 countries worldwide. It has been supplying printing ink to Bangladesh since the mid-nineties.

Before starting the Bangladesh operation, the company had customers in the country who used to import Siegwerk's inks from India.

During a factory visit to Siegwerk on Tuesday, company officials said the annual production capacity of the Bangladesh unit is 3,600 tonnes. The local production emphasises safe ink solutions through their latest blending technologies.

Toluene has earned disrepute globally for its bad toxicological profile. The manifold adverse effects make it an issue related to consumer safety, occupational safety, and environmental safety.

There have been various research studies that found that toluene – a chemical that is used in paint thinners – can easily cross the layers of packaging and potentially cause many health issues such as headaches, dizziness, hallucinations, memory loss and confusion.

Angshuman Mukherjee, country head of Siegwerk, said printing ink manufacturers use different chemical formulations and often hazardous substances to bring a variety of designs and colours, and for the longevity of the product.

"These could be cheaper packaging options, but the only 100% safe way is to go toluene-free," he commented.

According to the Siegwerk country head, the ink-maker primarily focuses on offering customised and individually formulated safe ink solutions.

He said inks produced at Siegwerk are compliant with global regulatory and brand owner requirements, ensuring products are safe for end-use packaging applications.

Angshuman Mukherjee said the authorities are drafting a food packaging guideline excluding the use of toluene-based ink, as they were asked for opinions about better food safety.

Local flexible packaging industries need 850 tonnes of ink per month, while Siegwerk accounts for 150 tonnes.

Apart from the German ink-maker, Japanese Sakata Inx Corporation and Chinese ADV Process Co Ltd are also making toluene-free packaging inks in the Meghna Economic Zone.