The technique involves lining a plastic bottle with microscopic y-shaped structures that cradle the droplets of soap above tiny air pockets, so that the soap never actually touches the inside of the bottle. The hard “y” structures are built up using much smaller nanoparticles made of silica, or quartz which, when treated further, won’t stick to soap.

The developers, Bahrat Bhushan and Philip Brown, say their solution is actually simpler and less expensive than alternatives under development. And it works for a common plastic used to package foodstuffs and household goods: polypropylene. Coatings already exist to help food, but not soap, pour out of their containers, which is harder.

The key is surface tension—the tendency of the molecules of a substance to stick to each other. Ketchup and other sauces are made mostly of water, and water molecules tend to stick to each other more than they stick to plastic. But surfactants—the organic molecules that make soap “soapy”—are just the opposite: They have a very low surface tension and stick to plastic easily.

The goal, which was suggested by a commercial shampoo manufacturer, was to create a shampoo bottle lining that was cheap, effective and environmentally friendly.

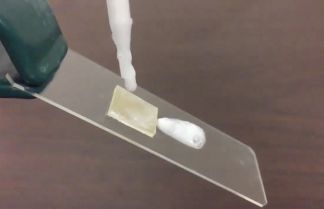

They came up with a method to spray-coat a small amount of solvent and ultra-fine silica nanoparticles onto the inside of bottles. Manufacturers already use solvents to change the texture of moulded plastics, because they cause the surface of the plastic to soften a little. By mixing the silica and solvent, the researchers were able to soften the surface of the polypropylene just enough that when the plastic re-hardened, the silica would be embedded in the surface.

Polypropylene isn’t the most common plastic bottle material, but it’s also used for yogurt tubs, ketchup bottles and medical bottles, single-serve coffee pods and Starbucks iced beverage cups. The invention could actually aid recycling by dispensing with the need to rinse the bottle.

With further development, the university hopes to license the coating technique to manufacturers, not just for shampoo bottles, but for other plastic products that have to stay clean, such as biomedical devices or catheters