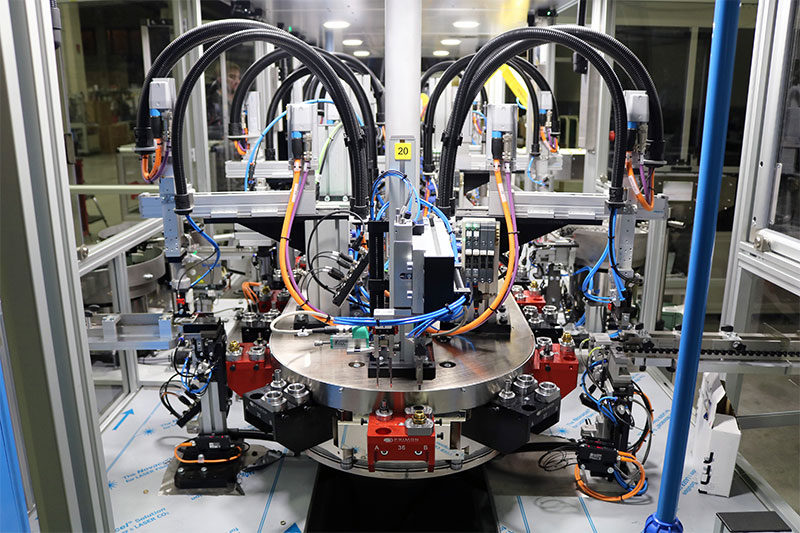

All subsequent stations are equipped with Festo- branded electric axes and brushless motors that have made it possible to satisfy the customer's requests, obtaining a modern and easily remodeled solution.

The machine has in memory the programs of all the connector configurations. According to the piece being loaded, the line is set automatically by adjusting all the strokes of the manipulators. To obtain this flexibility, Primon Automazioni has carried out a very important work at the software level to ensure ease of use for the operator. Furthermore, should the machine undergo technical updates due to the normal evolution of the components, in a short time it is possible to update the operation via software to keep it always in perfect operating efficiency.

From traditional pneumatics to electric axes: cooperation with Festo

The use of electric axes instead of traditional pneumatic actuators is a choice that Primon Automazioni has started for some time, obtaining important results in terms of reliability, flexibility and modularity. In this sense, Festo was the ideal partner for the technological leap, thanks to the combination of the new compact axes ELGC / EGSC and the performance of the new CMMT drive which, through its perfect integration with host systems, allows the collection, monitoring and data analysis, in line with Industry 4.0 logic. The Festo Automation Suite platform has also been used for some time, allowing remote management and tele-assistance, a well-established practice in the activity and service offered by Primon Automazioni.

The collaboration with Festo focuses on high productivity, reduced production costs and maximum customization, as well as flexibility in format change and ease of maintenance even remotely.