Company also will showcase grid lacquer coated paper and coated Tyvek® for device packaging, solvent-bondable TPE tubing, and more.

Wayne, PA – TekniPlex Healthcare, which utilizes advanced materials science expertise to help deliver better patient outcomes, will be highlighting its wide array of healthcare solutions at Compamed, November 13-16 in Dusseldorf, Germany. At Hall 8B, Stand N02, the company will showcase solutions ranging from medical compounds and tubing for medical devices to its grid lacquer coated paper and coated Tyvek® constructions for device packaging.

In the area of multilayer tubing, TekniPlex Healthcare is well versed in developing solutions for the transfer of sensitive drug products that contain preservatives, proteins, or other active ingredients prone to absorbing into the walls or surfaces of conventional tubing options. Recent examples include patented multilayer tubing configurations that offer extremely low absorption properties to help extend the usable life of insulin and other unstable drug products, such as chemotherapy drugs. Another patented configuration, designed for fluid transfer of DMSO and other solvent suspensions, features a polypropylene-based outer layer providing safe product delivery in dual hormone delivery systems and advanced cell and gene therapy processes.

The company also will be displaying multi-lumen tapered tubes, manufactured from Pebax® polymer, for endoscopic biliary procedures. For ease of handling by clinicians, the 2050 mm (81 inch) tubes transition from 2.45 mm (0.096 inches) on the proximal end to 1.72 mm (0.068 inches) on the distal end, which accesses the bile duct in the small intestine. A guidewire lumen, contrast lumen and balloon inflation lumen traverse the length of the tube to perform complex, minimally invasive procedures. The lumens are as small as 0.4 mm (0.016 inches) to 1.10 mm (0.43 inches), and retain consistently tight tolerances throughout the length of the tube.

The company also will be highlighting its medical device packaging offerings, including a variety of grid lacquer coated paper specifications and coated Tyvek® options. Early next year, TekniPlex Healthcare will be opening a new facility in Madison, WI, significantly boosting its lamination capacity for a broad range of materials including PET, nylon, paper, foil, PE, EAA and ionomer, in both peelable and non-peelable structures. The plant’s new coating and lamination assets will increase capacity for an array of products such as coated Tyvek® and reinforced papers.

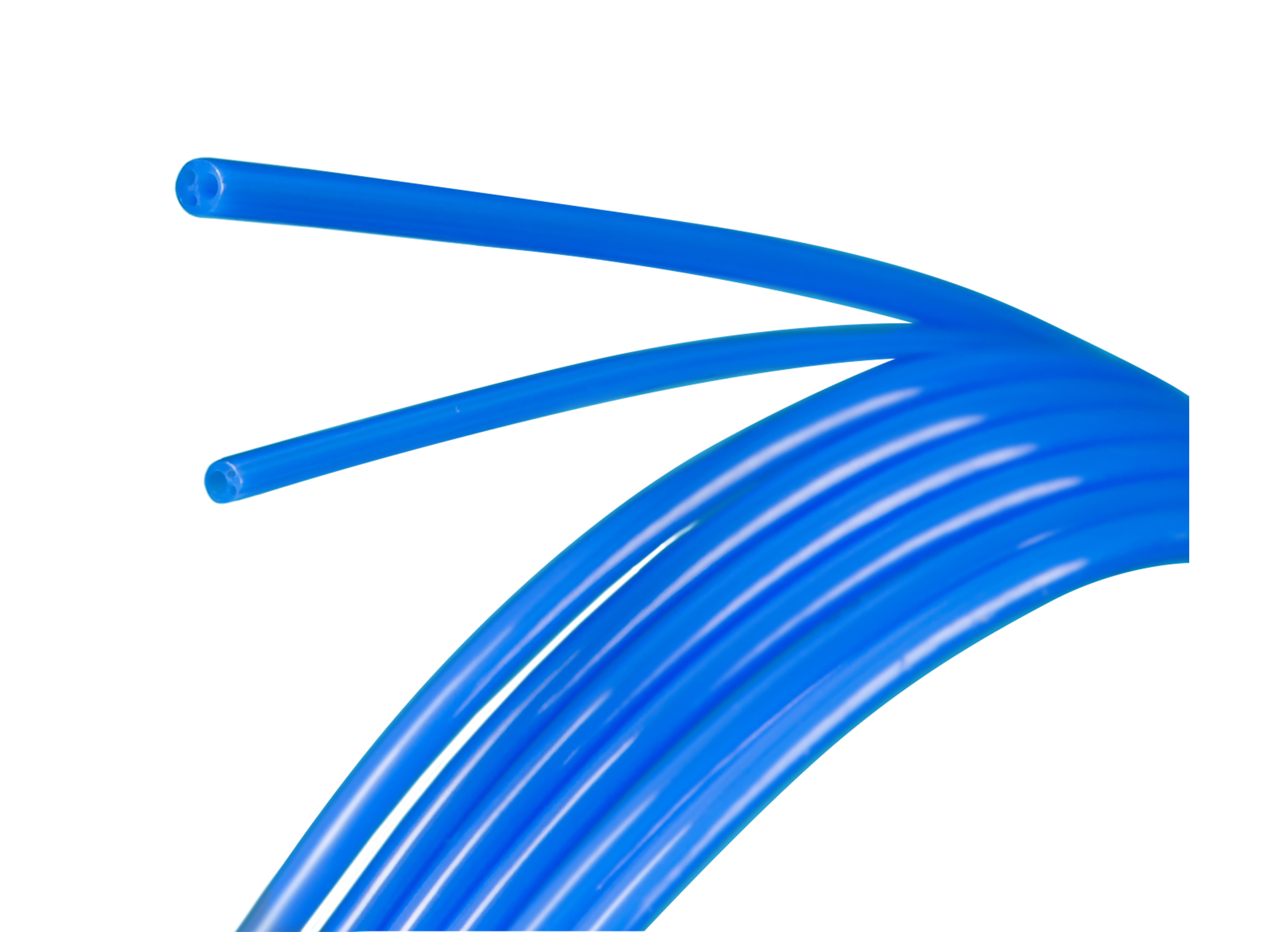

Another offering will be the company’s range of solvent-bondable thermoplastic elastomer (TPE) tubing produced with its proprietary compound formulations. An alternative to polyvinyl chloride (PVC), TekniPlex Healthcare’s range of thermoplastic elastomer compounds combine the performance benefit of vulcanized rubber with the processing properties of thermoplastics. Free of silicone, latex, phthalate and halogen, they are suitable for a wide variety of medical device tubing applications.

About TekniPlex Healthcare

TekniPlex Healthcare utilizes advanced materials science expertise and technologies to develop and deliver critical solutions for medical and diagnostic devices, drug delivery systems and healthcare packaging applications. With a global reach, the division’s deep understanding of the greater pharmaceuticals and medical landscape helps it produce exemplary barrier properties for drugs and precision medical devices for interventional and therapeutic procedures. TekniPlex Healthcare’s ever-evolving portfolio helps meet demands for high-leverage medicines and mission-critical healthcare products that benefit care providers and patients. For more information visit www.tekni-plex.com/healthcare.