Machine manufacturer KAMA, specialist for efficient finishing solutions for short and medium runs, will be showing live demos of converting and high-quality embellishment in digital printing at the Hunkeler Innovationdays 2023 in Lucerne, Switzerland (27. February to 02. March).

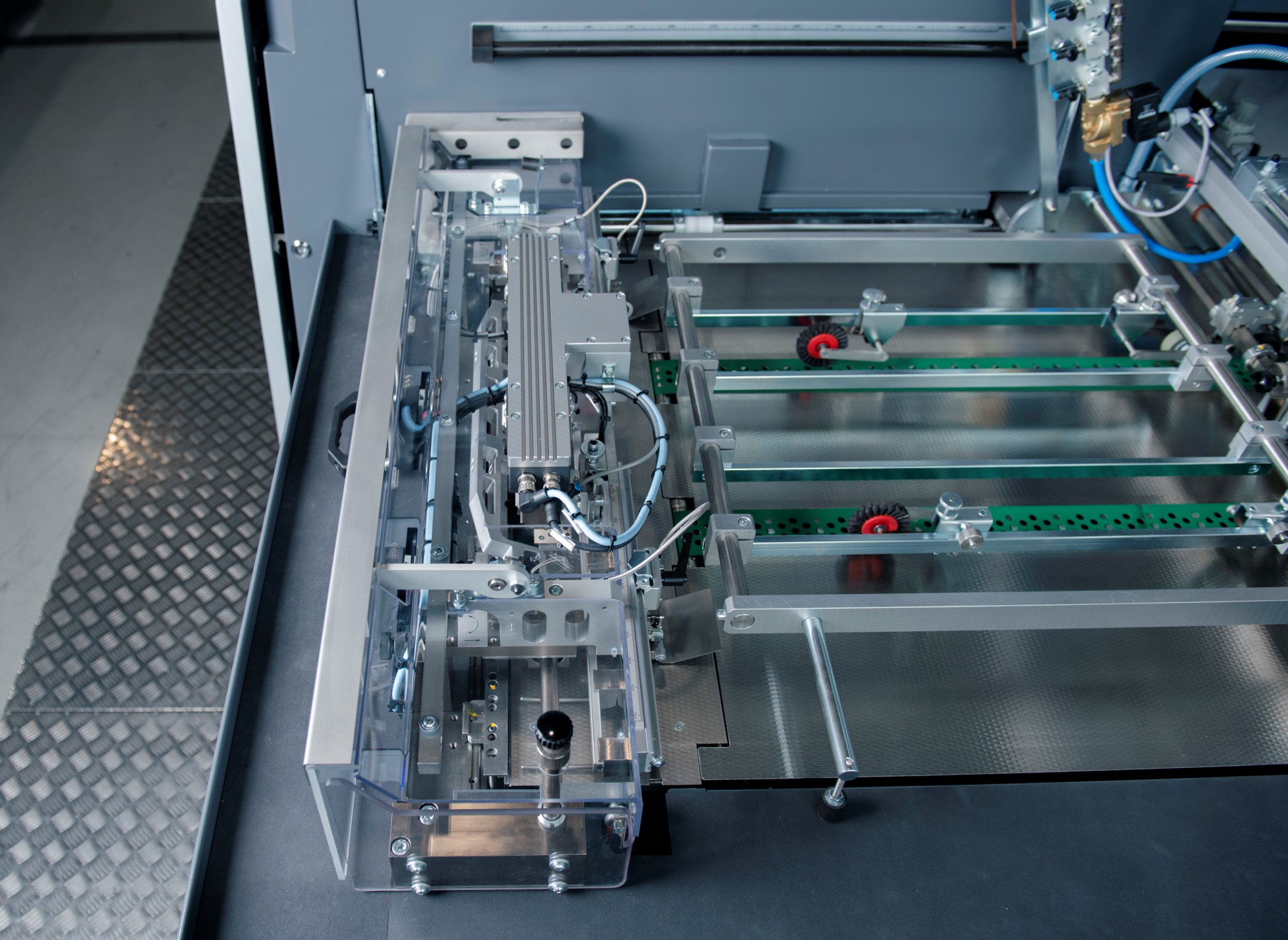

The Servo generation of the ProCut 76 Foil with advanced features and high automation is running at the KAMA booth in hall 1. The versatile machine covers a unique range of applications from die-cutting, creasing and perforating to embellishment with hot foil, hologram and relief, and meets the highest demands in finishing commercial jobs and folding carton production. KAMA presents the ProCut 76 Foil with the new AutoRegister AR3, which works with two cameras and brings every sheet exactly into position at full speed - ideal for finishing digital prints. The unique solution can be networked with the customer's server via the JobManager software as an interface.

First-class finishing, compact production

High-quality finishing is performed on the KAMA booth with impressive effects from nano, micro and multi-level embossing to hot foil reliefs. The servo main drive for asynchronous stroke control extends the contact time when transferring the pigments and ensures best finishing results even at high running speeds. The optimum foil feed is calculated by the Foil Saver software of the ProCut 76.

KAMA’s flagship finishing machine with up to three separately controllable foil feeders increases added value and opens up lucrative markets, such as for premium folding cartons for luxury items, chocolates, wellness products or cosmetics.

Depending on the requirements’ profile and production environ¬ment, the ProCut 76 Foil can be equipped with the mobile KAMA heating plate, a heatable honeycomb plate or an integrated head heating. The quick changeover from high-quality finishing to die-cutting/creasing with virtually no nicks will also be on show at the Hunkeler Innovationsdays.

Made in Germany

The versatile ProCut 76 Foil for the 760 x 600 mm format processes substrates up to 1,500 gsm as well as heat-treated, corrugated material with an output of up to 5,500 sheets per hour. The KAMA GmbH with an expertise of more than 125 years develops and manufactures all machines in its own production site in Dresden. www.kama.info