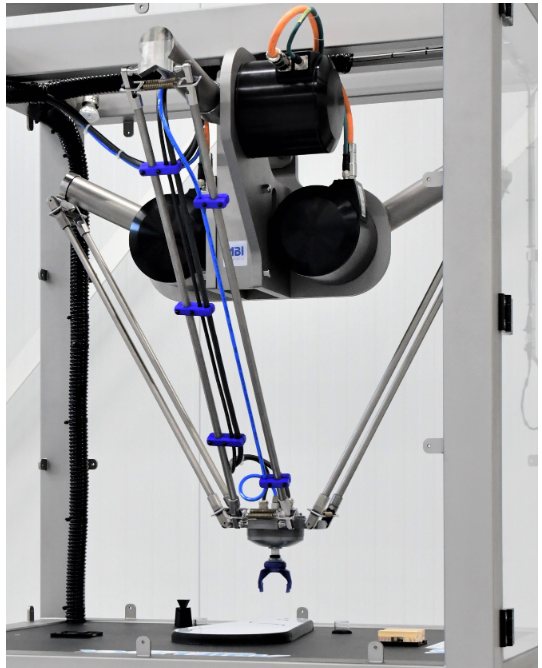

During the WOTS 2022 in Utrecht, ABI presented the latest innovation in the ABIFlexx delta robot series, the ABIFlexx with direct drive motors. This new variant is particularly fast, very accurate, quiet and low-maintenance. This makes this ABIFlexx direct drive robot the ideal solution for many different applications.

ABI has been developing and producing its own ABIflexx Delta robot program for over ten years: advanced robot systems that meet the most demanding requirements. These modular delta robot versions are available in various designs, including the patented Wide Delta robot that saves up to 50% space combined with a highly efficient working range.

A direct drive offers many advantages over the traditional drive combination of motor and reduction gear. The direct drive solution is energy efficient and extremely accurate, without backlash.

Due to the complete absence of oil-filled gear reductions, the mechanical limitations and life-limiting properties of these are no longer there and a maintenance-free, very quiet, fast, and accurate robot is created.

The ABIflexx Delta robot excels in production processes where hygiene plays a major role. Picking up, placing, and sorting packaged and unpackaged products, or cutting food.

Even more, flexibility is easily achieved by adding a gripper rotation. This drive is also a direct drive motor, fully integrated into the gripper plate.