Polymer scientists at IIT-Roorkee have claimed to have developed an indigenous technology to create "bio-based" packaging (colour) materials. They said with their technology, making counterfeit packaging of any product would be highly difficult.

A peer-reviewed scientific journal - ACS Applied Nano Materials - - has published its study in its recent issue. To fulfil their objective of a bio-based technology, researchers used bagasse (agro-waste sugarcane) and organic acids (As) like citric, malic and tartaric acids, etc, after extracting from orange, apple and tamarind.

"Till now, the provision of barcodes is being made available by the packaging industry of any product to stop counterfeit practices. However, barcodes can also be counterfeited. But our technology is secured from counterfeit as our packaging sensors (colour materials) are transparent in nature and can only be detected after the use of UV light. A market-available UV torchlight will help detect the colour (as a code) on a strip pasted on the packaging wrappers," said prof Pradip K Maji, principal investigator of the Project.

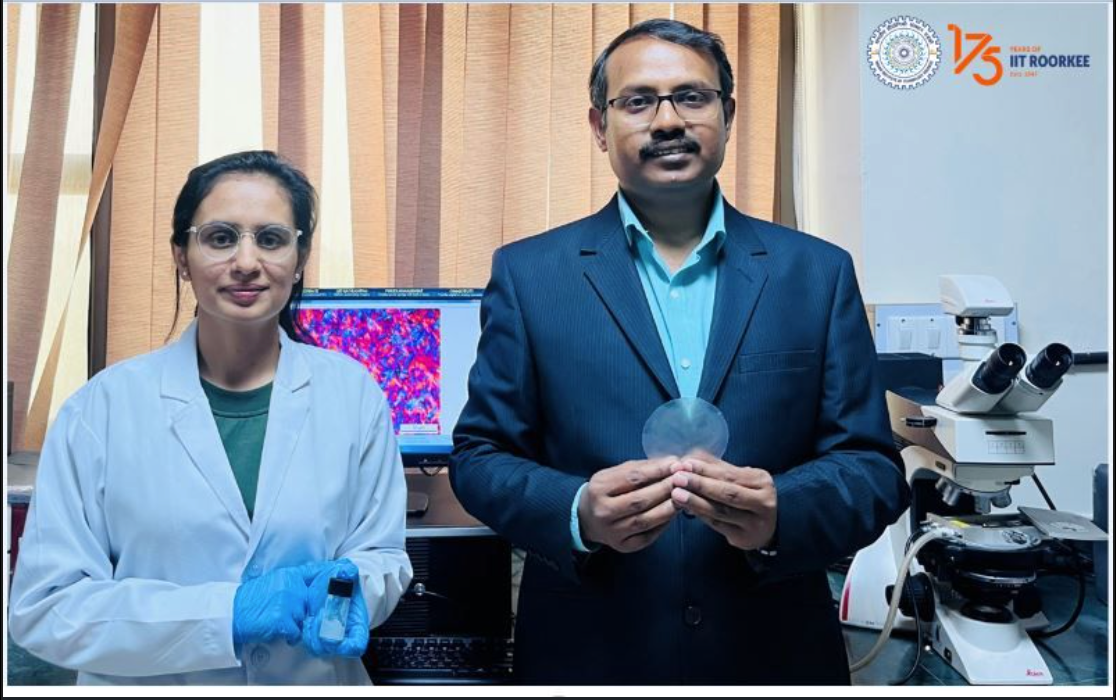

The other researchers associated with this project were Chhavi Verma, Saurabh K Kardam, Monika Chhajed and Upendranath Nandi.

According to Chhavi Verma, they obtained cellulose nanocrystal (CNC) films from bagasse and added layers of different As under many stages of the laboratory process. By this, they got flexible and transparent films that displayed good visual colour-sensing properties with moderate antibacterial activity for Escherichia coli bacteria.

"This process is divided into stages of bleaching raw fibre and acid hydrolysis of cellulose pulp under standardized conditions. She added that the final CNC suspension is then concentrated to make it behave as a liquid crystal material showing birefringence (splitting of light) properties.

The CNC of bagasse has an inherent quality of colours that cannot be seen by the naked eye. Researchers have obtained the desired colour through "modification techniques" of biopolymers after adding As in layer-by-layer assembly. The researchers have succeeded in making packaging sensors for blue and red colours so far and other sensors are still underway in the institute's laboratory at the Saharanpur-based campus.

"Apart from the fact that it is an intelligent packaging material, it does not have the quality of any toxic-based material, ultimately a cost to the environment. We are receiving offers for technology transfer from local packaging industries after the publication of our research paper but before going to technology transfer dissemination we have to get the first patent on our technology, said Maji.