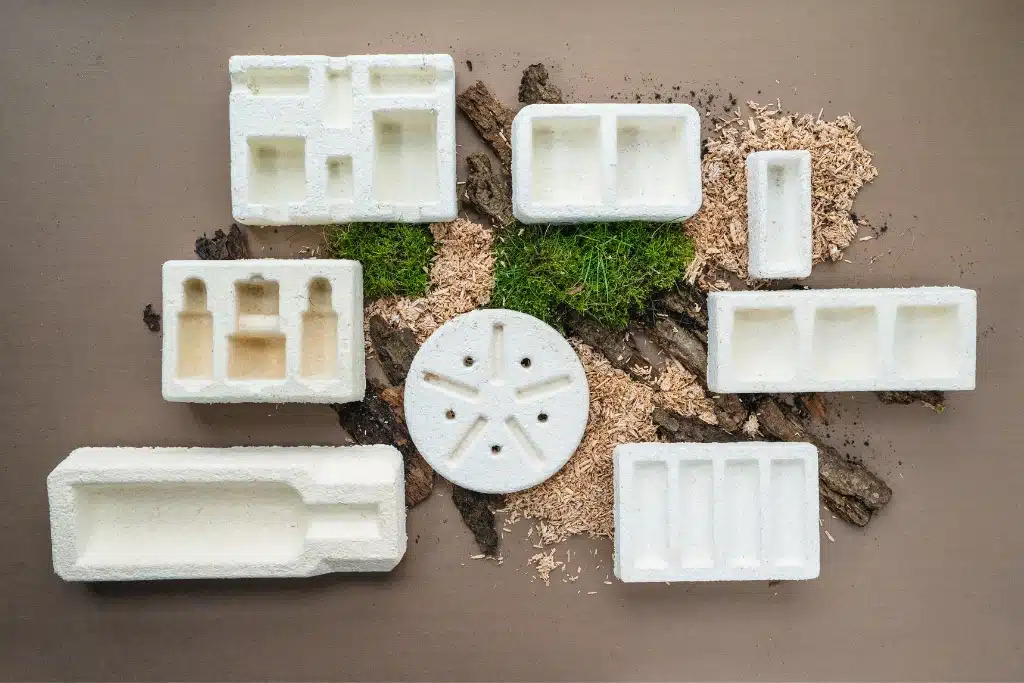

Mycelium-based packaging is a sustainable alternative to traditional plastics, leveraging the root network of fungi to create biodegradable, compostable materials. It's made by combining mycelium with agricultural waste like corn stalks or wood chips, which the mycelium binds together, forming a solid, moldable structure. This process results in a lightweight, durable, and flexible material that can be tailored to various packaging needs, including replacing polystyrene.

Here's a more detailed look at mycelium-based packaging:

-

What it is: Mycelium is the root-like network of fungi, often found underground.

-

How it's made: Mycelium is grown in molds filled with a substrate, such as agricultural waste, and then heat-treated to stop further growth and create a durable, compostable product.

-

Materials: Mycelium can be combined with various materials like corn stalks, hemp hurds, wood chips, and even sawdust.

-

Properties: Mycelium-based packaging is biodegradable, compostable, lightweight, and can be molded into various shapes.

-

Benefits: It's a renewable resource, requires minimal resources to grow, and provides excellent end-of-life performance, degrading naturally in composting environments.

-

Applications: Mycelium packaging can be used for a wide range of products, including food packaging, insulation, and even as a substitute for expanded polystyrene (EPS).