MGC Unveils OXYCAPT: A Game-Changer in Pharmaceutical Packaging

Mitsubishi Gas Chemical (MGC) has introduced OXYCAPT, an innovative plastic vial that successfully combines the strengths of both glass and plastic, while overcoming their long-standing limitations in pharmaceutical applications.

Traditional materials used for vials and syringes have posed significant challenges—glass is prone to breakage and chemical instability, while plastic often fails to provide sufficient barriers against oxygen and UV light. In response to these concerns voiced by the US FDA and leading pharmaceutical companies, MGC developed OXYCAPT, a breakthrough solution that addresses these shortcomings.

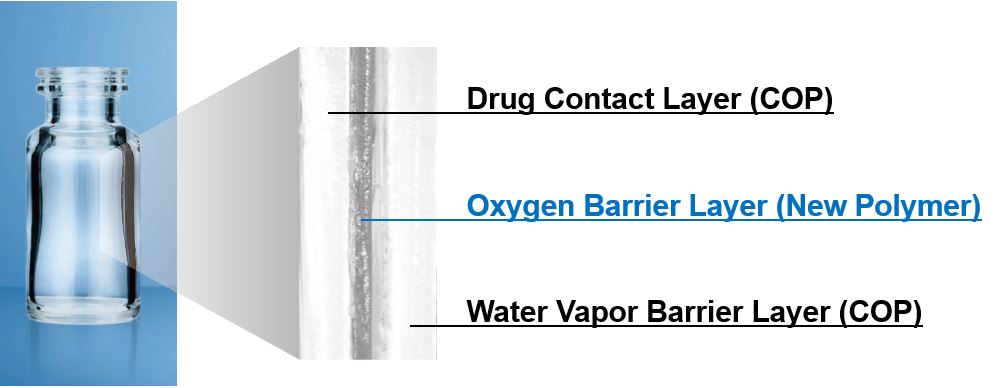

OXYCAPT is a lightweight, multilayer vial crafted from advanced materials. It features a three-layer structure that includes:

-

A drug-contact layer made from Cyclo Olefin Polymer (COP), known for its chemical resistance and low extractables.

-

A middle oxygen barrier layer that significantly reduces oxygen permeability.

-

An outer protective layer, contributing to the vial’s overall durability and integrity.

This novel construction offers exceptional benefits such as high oxygen and moisture barrier performance, low protein adsorption, and enhanced break resistance, making it ideal for the safe and stable storage of sensitive biologics and other injectable drugs.

With OXYCAPT, MGC sets a new standard in pharmaceutical packaging—merging safety, performance, and reliability in a single vial.

Why OXYCAPT Stands Out: Advancing Drug Stability and Patient Safety

OXYCAPT is not just an alternative to traditional packaging—it’s a breakthrough that enhances the shelf life, safety, and performance of pharmaceuticals.

Its exceptional oxygen and CO₂ barrier capabilities ensure that sensitive medications are better protected from degradation. Unlike traditional materials, OXYCAPT also offers inorganic extractables at levels even lower than Type I glass, making it one of the safest choices for drug containment.

Thanks to its superior UV absorption, OXYCAPT helps maintain the stability and potency of drugs by shielding them from harmful light exposure—an advantage that significantly extends the product’s efficacy throughout its lifecycle.

This makes OXYCAPT particularly well-suited for complex formulations such as biologics, biosimilars, and advanced therapies like gene and cell therapies. Its low extractables, high break-resistance, and strong oxygen and UV barriers provide a robust packaging solution tailored to the stringent demands of next-generation pharmaceuticals.

As pharmaceutical companies look to the future, OXYCAPT emerges as a next-level material that redefines industry standards in drug safety, stability, and performance.

OXYCAPT in Action: The Ideal Choice for Biologics and Advanced Therapies

Designed specifically for modern pharmaceutical needs, MGC’s OXYCAPT vials are proving to be the preferred packaging solution for biologics, cell and gene therapies, and other injectable liquid medications.

These multilayer plastic vials offer a superior alternative to traditional containers, effectively addressing critical issues in drug storage. Long-term studies have shown that OXYCAPT provides greater drug stability and extended shelf life than conventional COP containers—primarily due to its exceptional oxygen barrier. Unlike glass, OXYCAPT completely eliminates delamination, a common issue where microscopic flakes form due to glass degradation, posing a risk to drug purity.

OXYCAPT also solves visibility and stability concerns associated with conventional plastics, making it a more reliable and consistent packaging solution. Its advanced construction features a CO₂ barrier and resistance to ultra-low temperatures, which has become increasingly important with the rise of next-generation therapies requiring cryogenic storage and dry ice transport.

With its proven performance across multiple critical parameters, OXYCAPT is setting new benchmarks in drug safety, stability, and packaging innovation—making it a trusted choice among leading pharmaceutical companies worldwide.

The OXYCAPT Advantage: Setting a New Standard in Barrier Performance

Oxygen & CO2 Barrier

OXYCAPT-P Vial has high oxygen & CO2 barrier property. The oxygen & CO2 barrier is about 20 times better than COP. The result ensures consumers, pharmaceutical companies, biopharmaceutical companies, and entrepreneurial ventures looking to deliver biosimilars, biomedicines of advanced biologics, and cell/gene therapy products, receive effective medication after longer periods of storage time.

UV Barrier

Pharmaceutical companies heavily focus on improving UV barriers of packaging container materials because UV deteriorates drug contents and stability. Through UV absorption, OXYCAPT protects drugs better than COP and Glass Type I by cutting off UV light below 300 nm.

Inorganic Extractables

Increased scrutiny by regulators has led the medical, pharmaceutical and biopharmaceutical industry to focus on inorganic extractable assessments to ensure patient safety and drug interaction. OXYCAPT outperforms all plastic and glass advanced materials—including Type 1 Glass, COP, PP, and PE—currently on the market.