The special 38mm finish allows the cylinder and closure components to work together, creating a CPSC-approved child resistant container. Both components offer increased sustainability for companies that are exploring ways to reduce their carbon footprint.

Packaging sustainability is built in

As climate change becomes more evident, protecting our environment continues to be a concern for all of us. That’s why Drug Plastics is committed to offering products that help increase packaging sustainability. For instance, we continue to explore alternatives to traditional plastic resins. Our family of Pop & Click Cylinders is available in FDA-approved virgin HDPE. However, if you are looking for a more environmentally-friendly option, these cylinders are also available in FDA-approved Post-Consumer Recycled (PCR) HDPE. PCR resins take plastic discarded by the consumer out of the environment and process it back into resin that can be used again and again.

This creates a sustainable circular economy where raw materials are created from recycled resources. Greenhouse gasses and carbon footprint are reduced in this circular economy. PCR HDPE is virtually identical to virgin HDPE and can be placed into the current recycle stream. Making the switch to PCR resin is an easy way to have a big impact on the environment.

Designed to support source reduction

The exclusive closure that works with the Pop & Click Cylinders are available in FDA-approved virgin Polypropylene (PP). These specially designed one-piece closures use significantly less plastic than traditional two-piece push and turn closures.

Compared to an equivalent 38mm push and turn closure, the Pop & Click closure reduces your carbon footprint because it uses almost 65% less plastic. How’s that for source reduction? The closures come standard with a molded TPE re-seal liner which functions as a gasket to protect the package contents. A heat induction liner is optional.

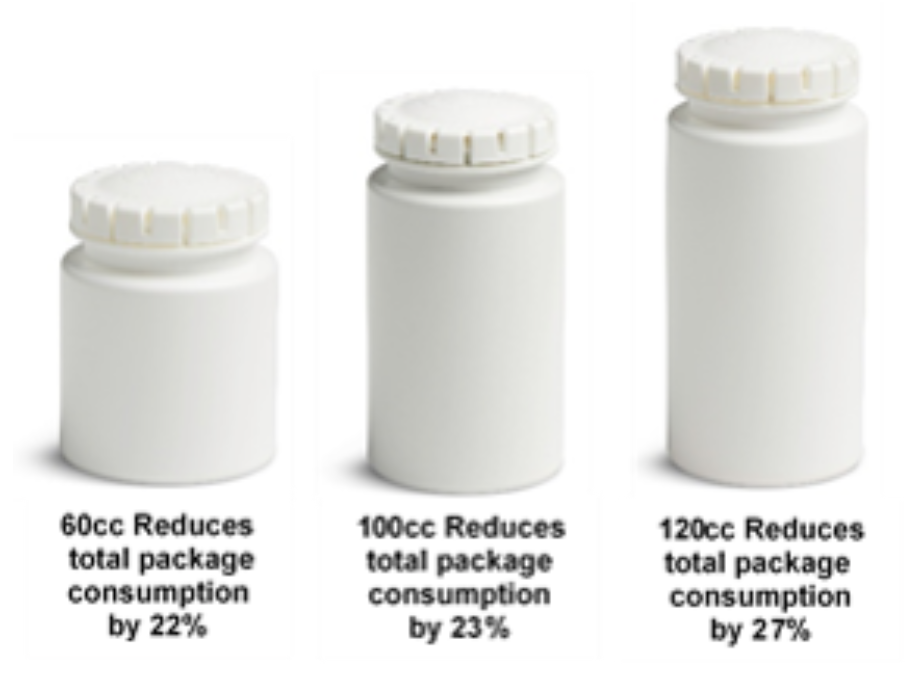

When you calculate the source reduction for the entire package, our 60cc Pop & Click Cylinder and 38mm closure reduces plastic consumption by 22% over a similar cylinder with a two-piece push and turn closure. The 100cc package saves 23% plastic, while the 120cc package saves 27% plastic.

More child resistant, more senior-friendly

With 100% effectiveness before demonstration and 98% effectiveness after, Pop & Click Packaging passed full CPSC child safety protocol with outstanding results. Rest easy knowing this packaging system is a proven deterrent to inquisitive children.

Yet it’s also senior-friendly. Even with its high marks for child safety, 86% of seniors tested still rate Pop & Click packaging easier to open than other child resistant systems. Hands-free opening and closing options make Pop & Click a great choice for seniors and those with limited finger mobility.

Stand out from the crowd

Pop & Click is an attention-getter. Because of its unique look and the novel way it opens, Pop & Click differentiates your product packaging from the competition. This system is a great way to create new excitement around your brand and attract more consumers.

When you choose Pop & Click packaging, you also show your customers that you are taking steps to use more sustainable packaging and to conserve natural resources for future generations. Your customers will appreciate your efforts to be more planet-friendly, in turn, helping to increase customer loyalty, confidence, and overall positive brand identity for your products.

If you are looking to reduce your carbon footprint, Pop & Click packaging is an excellent choice.