In partnering with PUMA, a leader in sportswear, shoes and products, we looked to create a game changing packaging system that would greatly reduce their footprint and build on their initiatives toward cleaner, greener, and safer practices contributing to a better world around us. The challenge was to look at one of the most difficult and stagnant issues facing the retail industry in regards to sustainability and environmental harm: packaging, and more specifically shoeboxes. Boxes contribute to millions of tons of waste a year and even with proposed second uses, they are eventually thrown out.

Strategy

Already known as a company willing to take risks and push boundaries, Puma approached fuseproject to see what improvements could be made in the way its shoes and apparel are packaged and shipped worldwide. The goals were to reduce environmental impact and reduce cost where possible.

We embarked on a two month journey to understand where and how the current packaging was made, how it was transported, handled, packed and stored all the way through to delivery into the customer’s hands. To succeed, our new solution must work with minimal to no changes to existing infrastructure. Through diagrams, photographs and interviews we documented and mapped the supply chain, indicating key requirements and areas for improvement at each step.

Rooted in these insights, we designed an innovative solution called the clever little bag, which saves 20 million megajoules of electricity, 1 million liters of water, 500,000 liters of diesel fuel (lighter weight), and 8,500 tons of paper per year. At the same time, the solution is reusable for the consumer, and fully recyclable at the end of its life.

Product

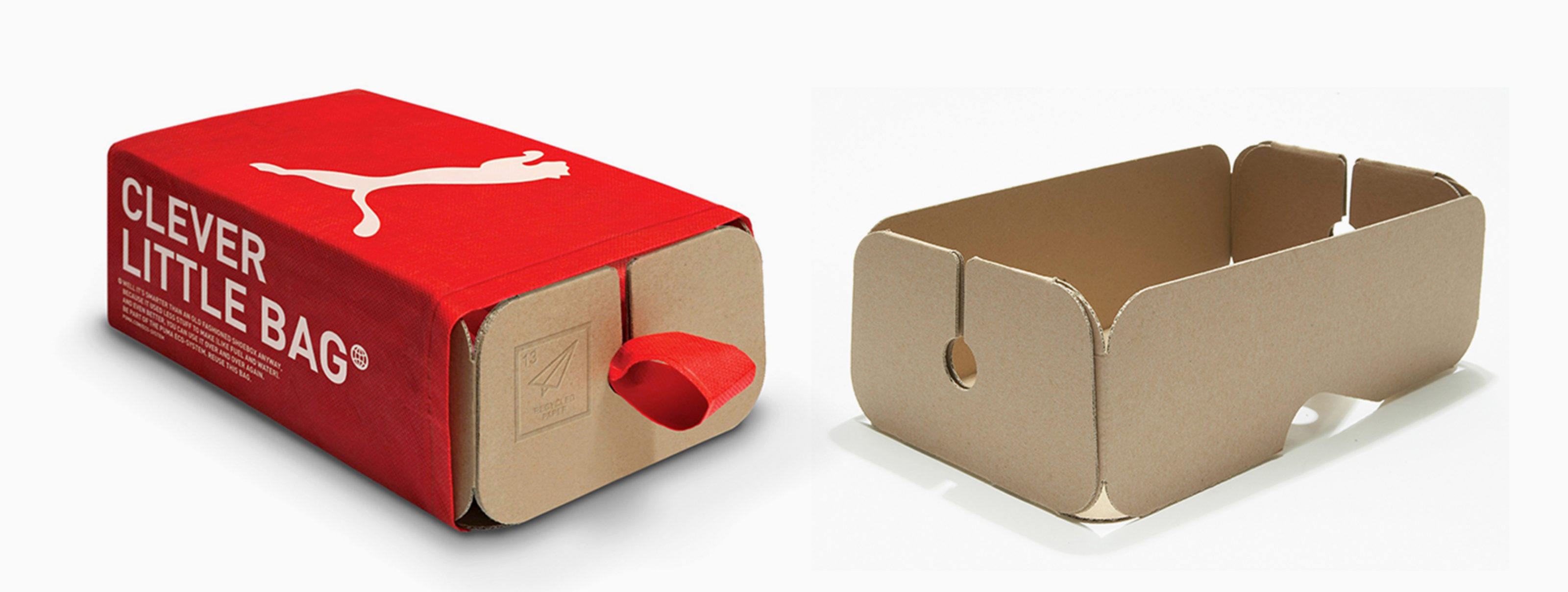

The cardboard structure is die cut from one flat piece of material and has no additional printing or assembly, thus it can be returned to the stream faster and more efficiently. The structure was created with four walls that taper in to allow for secured stacking, another important element left over from the original shoebox. The bag is non-woven which means less work and waste (it is stitched with heat). It protects the shoes from dust and dirt in the warehouse and during shipping.

The “clever little bag” is an iconic brand element upon leaving the store as it replaces the plastic shopping bag, and can also be repurposed for creative reuse. The bag is made of non-woven polyester consisting of polypropylene, and eventually is also recyclable. With our ‘clever little bag’, Puma kicks-off the next pivotal phase of it’s sustainability program. The tens of millions of shoes shipped in our bag will reduce water, energy and diesel consumption on the manufacturing level alone by more than 60% per year.

In other words: approximately 8,500 tons less paper consumed, 20 million Mega joules of electricity saved, 1 million liters less fuel oil used and 1 million liters of water conserved. During transport 500,000 liters of diesel is saved and lastly, by replacing traditional shopping bags the difference in weight will save almost 275 tons of plastic. That such a little bag can have such a big impact...you can see why we called it clever.