In the industrial and petrochemical industries, these steel drums contain hazardous and high value chemicals. However, as the steel drum industry grows, so does the counterfeiting globally, with an average growth rate of 14.9% from 2017-2020.

At Rieke, they understand the impact that counterfeiting has on brand reputation, the thousands of monetary losses and the danger of counterfeited solutions. These counterfeit solutions sometimes expose the end consumer to health and safety dangers.

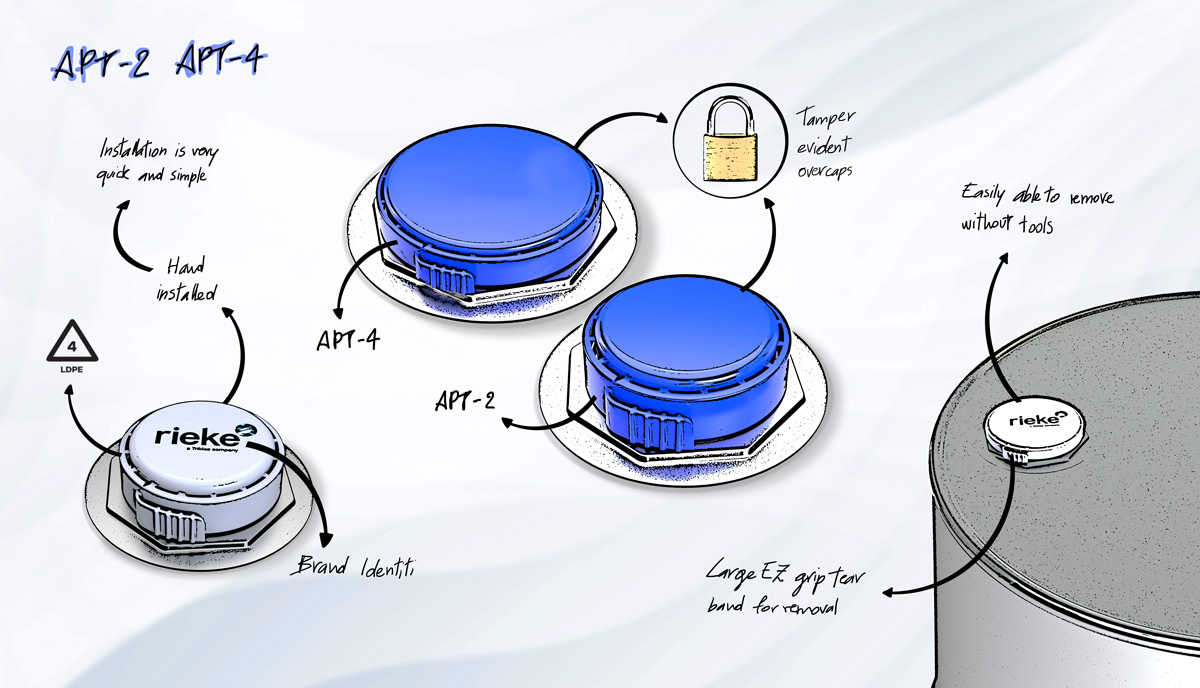

In order to protect customers’ brand reputation, Rieke stepped to the challenge by extending its tamper evident overcaps range. Rieke’s APT-2 & APT-4 tamper evident overcaps, ensures that product has not been tampered with in transit to its destination.

Rieke's APT-2 & APT-4 tamper evident overcaps, feature an Eco-friendly TE band, that avoids circular plastic waste. That is not all, their tamper evident over cap has a smooth, printable surface for brand identity to enhance and protect brand.

Tamper evident overcaps created to add additional security against product counterfeiting. Provides the perfect solution for industrial chemicals.

Key Features

- All plastic capseal

- Designed to fit properly Installed ISO/FDIS 15750-3, Type A & C, Octagon Base Closure Systems

- Manufactured from LDPE materials

- Smooth, printable surface for brand identity

- Hand installed : no specific tooling required

- Large EZ grip tear band for removal

Benefits

- Protects against contamination from water, dirt and debris

- Offers best in class protection against product tampering

- Print can alert customers to important chemical safety information and care instructions

- Recyclable all-plastic tamper evident seal

- Smooth, printable surface for brand identity