Bayer and Liveo Research Unveil Groundbreaking Eco-Friendly Blister Packaging

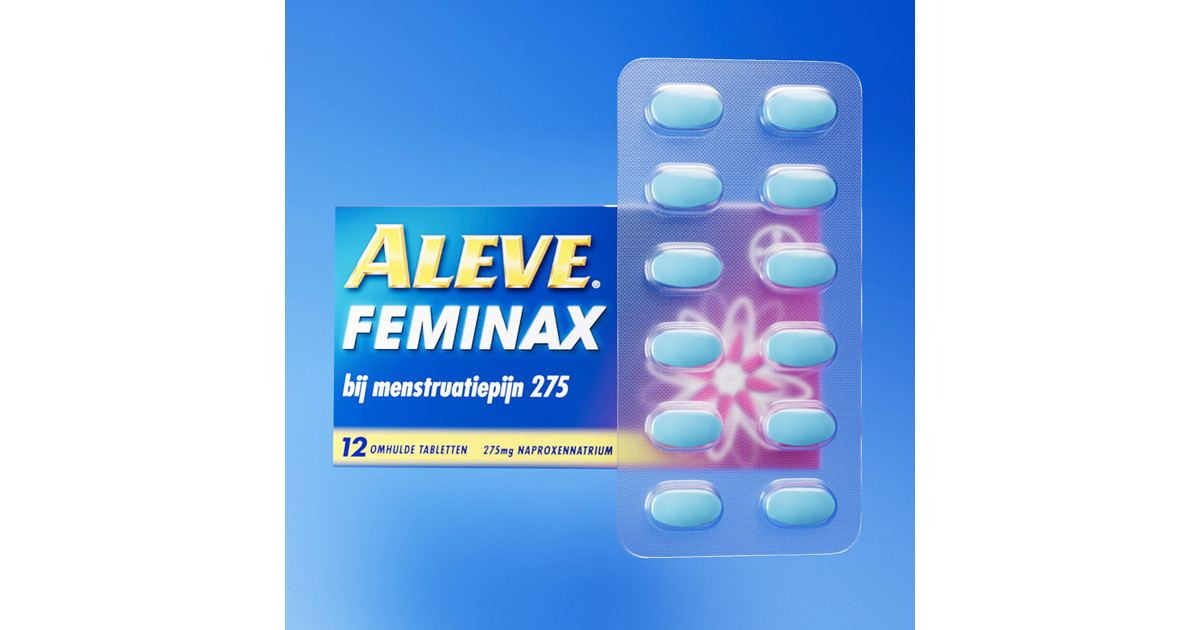

Basel, Switzerland, – Bayer, in collaboration with pharmaceutical packaging specialist Liveo Research, has introduced a revolutionary step toward sustainable healthcare packaging. The duo has launched the first-ever polyethylene terephthalate (PET) blister packaging for Bayer’s iconic Aleve brand, setting a new standard for environmental responsibility in over-the-counter medicine packaging.

This innovation significantly reduces the environmental footprint of blister packaging, achieving a remarkable 38% reduction in carbon emissions per unit compared to traditional packaging. By eliminating the use of polyvinyl chloride (PVC), Bayer has taken a decisive step toward creating recyclable, single-material packaging—a long-standing challenge in the pharmaceutical industry.

Smarter Packaging, Smaller Impact

The PET-based blister packs offer substantial environmental benefits:

- 38% Reduction in Carbon Footprint: A significant step toward mitigating climate change.

- 78% Less Water Use & 53% Less Land Impact: Helping preserve critical natural resources.

- 18% Lighter Packaging: Improving resource efficiency.

Beyond its environmental benefits, the PET packaging maintains Bayer’s commitment to delivering safe, high-quality products without added cost to consumers. Launching initially in the Netherlands, Bayer plans to roll out the eco-friendly packaging globally across its product portfolio in the coming years.

Sustainability without Compromise

“This new blister packaging reflects our commitment to deliver exceptional consumer experiences while minimizing our impact on the planet,” said Chris Padain, Vice President and Global Head of Design, Packaging, Product Experience & Sustainability at Bayer Consumer Health. “It’s an important milestone in our journey to create circular, sustainable solutions.”

Dr. Carsten Heldmann, CEO of Liveo Research, echoed this sentiment, stating, “With the PET One-Material Blister, we’ve demonstrated that sustainability and large-scale pharmaceutical packaging can go hand-in-hand. This innovation saves both CO2 and waste, proving the potential of sustainable solutions today.”

Driving Industry-Wide Change

While PET is widely recyclable in other industries, Bayer is proactively addressing the challenges of recycling pharmaceutical packaging. Collaborating with the Global Self-Care Federation, the Blister Pack Collective, and The Recycling Partnership, Bayer is leading efforts to improve recycling infrastructure and create systemic change.

From pioneering research on circular packaging to advocating for better recycling systems, Bayer’s bold move with PET blister packaging underscores its dedication to driving sustainability in healthcare packaging—ensuring safer, greener solutions for both people and the planet.