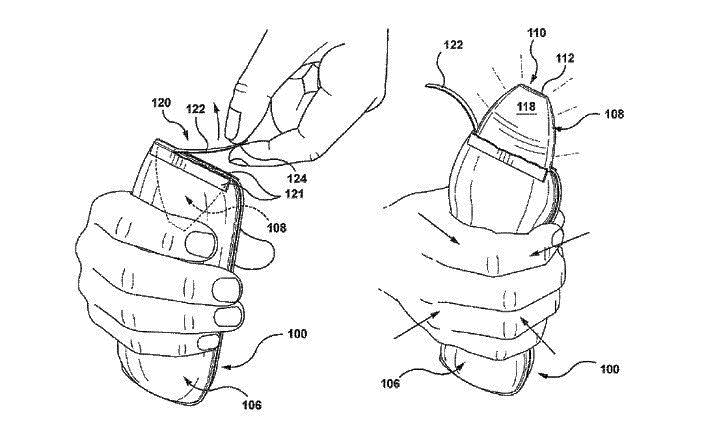

A new packaging concept offers a twist on the popular plastic pouch for beverages and other liquid products: the Inverta-Pouch. The recently patented design ensures the contents can be opened and consumed safely and hygienically using only one hand regardless of where the package has been. The key is a novel feature: an inverted neck tucked inside the pouch.

“We hope to accelerate packaging innovation that’s focused on consumer safety and convenience, while reducing material usage and weight to reduce shipping costs,” says Jim Bojeczko, cofounder of BB Packaging Concepts, a packaging design startup in Toronto, Canada.

“With the heightened sensitivity due to the pandemic, a hygienic means of dispensing consumable liquids will be very compelling for an innovative beverage company or packager looking to capture market share,” adds BBPC co-founder Greg Blysniuk, who responds to our questions in an exclusive interview.

But first, some key facts…

- It’s made of two parts, a plastic film pillow pouch and a plastic clip fitment;

- It’s been in development for about two years including the patent process;

- It’s appropriate for liquids and gels including water, alcohol, energy, and sports drinks, pharmaceuticals, and medicines;

- The inventors envision size of 1 to 2.7 ounces (30 to 80 ml);

- Usage occasions include fitness and other activities, travel, workplace, military, and disaster relief.

What sparked the idea?

Blysniuk: Jim’s son, a fitness buff, was going for a run and asked if his dad had a little squirt bottle to use just to keep his mouth from getting dry. He felt that plastic water bottles or insulated bottles and the like were heavy, awkward, and inconvenient…not at all conducive to running.

That led Jim to the idea of a small-volume, single-use pouch on a lanyard — a lightweight, one-hand operation that was easy to dispense, hygienic, and wouldn’t leak. He shared it with me, we developed a prototype, decided to work on a patent, and Inverta-Pouch was born!

How would it be assembled and filled?

Blysniuk: We envision that the pouch with the inverted neck and clip would be manufactured and shipped with the open bottom unsealed. The packager would fill the contents and seal the pouch bottom.

What's the cost premium vs. a standard pouch?

Blysniuk: We don’t have detailed costing information, but we believe it would be comparable to pouches already in-market that feature a plastic fitment.

What interest have you experienced?

Blysniuk: The reaction has been positive. Before approaching any beverage companies, we successfully conducted cold calls with two US-based packaging companies. The discussions were focused on potential consumer applications and on manufacturing viability.

Also, through some networking activity though a packaging consultant we've engaged we were connected to a business development VP for a filling company located on the west coast of Canada. They asked if Inverta-Pouch was yet in production yet, as some of their clients were looking for a new way to pack food sauces and soups in pouches for high-pressure processing (HPP) treatment.

What's the status?

Blysniuk: It's currently at the concept stage. Our objective is to establish a relationship with an industry partner, either a packaging manufacturer or a beverage company, to take this to market.