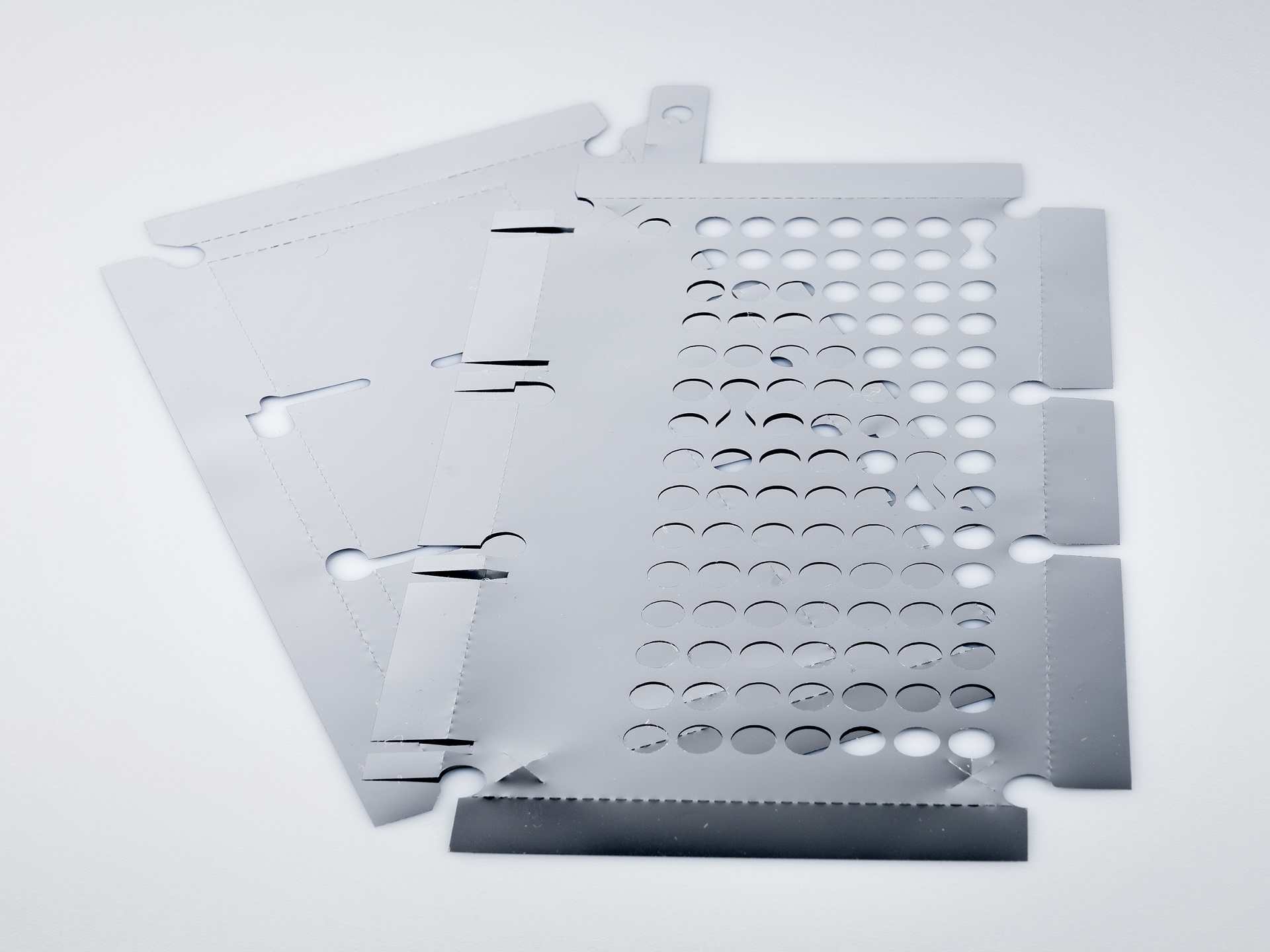

In the event of inadequate shielding, electromagnetic waves and electrostatic fields cause unwanted voltages and currents resulting in mutual interferences of neighboring equipment. The consequences are audible humming, functional impairments and signal interferences (e.g. of sensors and electronic control units), plus a higher risk of fire due to overloads up to and including total equipment failure. Protection films for EMI shielding from Schreiner ProTech provide relief: They reduce the hazards emanating from electromagnetic radiation. The films consist of electrically conductive materials such as metallized films, metal foils, metallized foam and metal fabrics. The frequency of the radiation is an important factor in selecting the shielding film: the lower the frequency, the larger the wavelength and penetration depth of the radiation. The film’s shielding effect depends on the material’s properties, the geometry and the assembly conditions. All films are optimized to suit the customer’s specific application. Customers test the shielding in real-world conditions at their own sites. Electromagnetic compatibility (EMC) refers to a technical device’s ability of not interfering with other devices due to unwanted electrical or electromagnetic effects and not to be interfered with by other devices. Electromagnetic interference (EMI) refers to effects on the functionality of electrical circuits, devices and systems caused by magnetic and electrical fields. Full-Service Package Schreiner ProTech offers an extensive range of modified processing systems supporting the application of EMI protection films. They can be customized to suit specific requirements. As a result, the customer receives a total solution from a one-stop shop in which the individual components are optimally.