Described as “disruptive for the powder-bed fusion technology market,” a new eco-friendly polymer for 3D printing developed by Jabil Inc. reportedly delivers “strength, chemical resistance, and resilience in comparison to general-purpose nylon materials such as PA 12.”

The patent-pending material improves upon existing polymers to offer enhanced processing and performance properties, said Matt Torosian, Director, Product Management, Jabil Additive. “With PK 5000, we are introducing new innovations to meet a broad range of customer requirements while accelerating the adoption of additive manufacturing.” It is suited for demanding automotive, consumer electronics, defense, medical, and industrial manufacturing applications, according to Jabil.

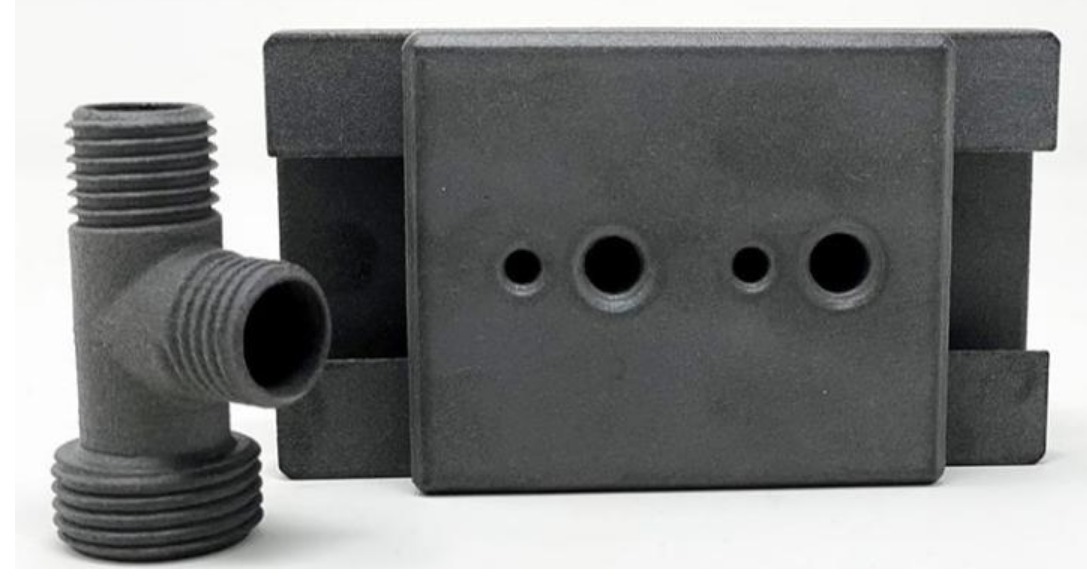

The material combines chemical and mechanical properties, such as high-impact strength, high-abrasion resistance, and improved elongation over other nylon materials to withstand functional testing and use. PK 5000 also has high-barrier properties and low-moisture absorption, which may be critical for ensuring the quality and resilience of certain parts and products exposed to fuel and water, according to Jabil. The polyketone resin used to make PK 5000 is a low-carbon material made from carbon monoxide. The ability to leverage carbon monoxide, which is a leading cause of atmospheric pollution, may reduce the overall carbon footprint.

EOS, Farsoon, and 3D Systems are currently evaluating PK 5000 for their printer platforms. Jabil is developing process parameters for all major SLS platforms to ensure widespread access.

PK 5000 was created, tested, and validated at Jabil’s Materials Innovation Center in Chaska, MN. At the center, experienced additive manufacturing engineers, chemists, materials scientists, and production experts leverage Jabil’s innovations in materials science to oversee each step of the beaker-to-box process of developing customized powders and filaments under an ISO 9001-2015 quality management system.