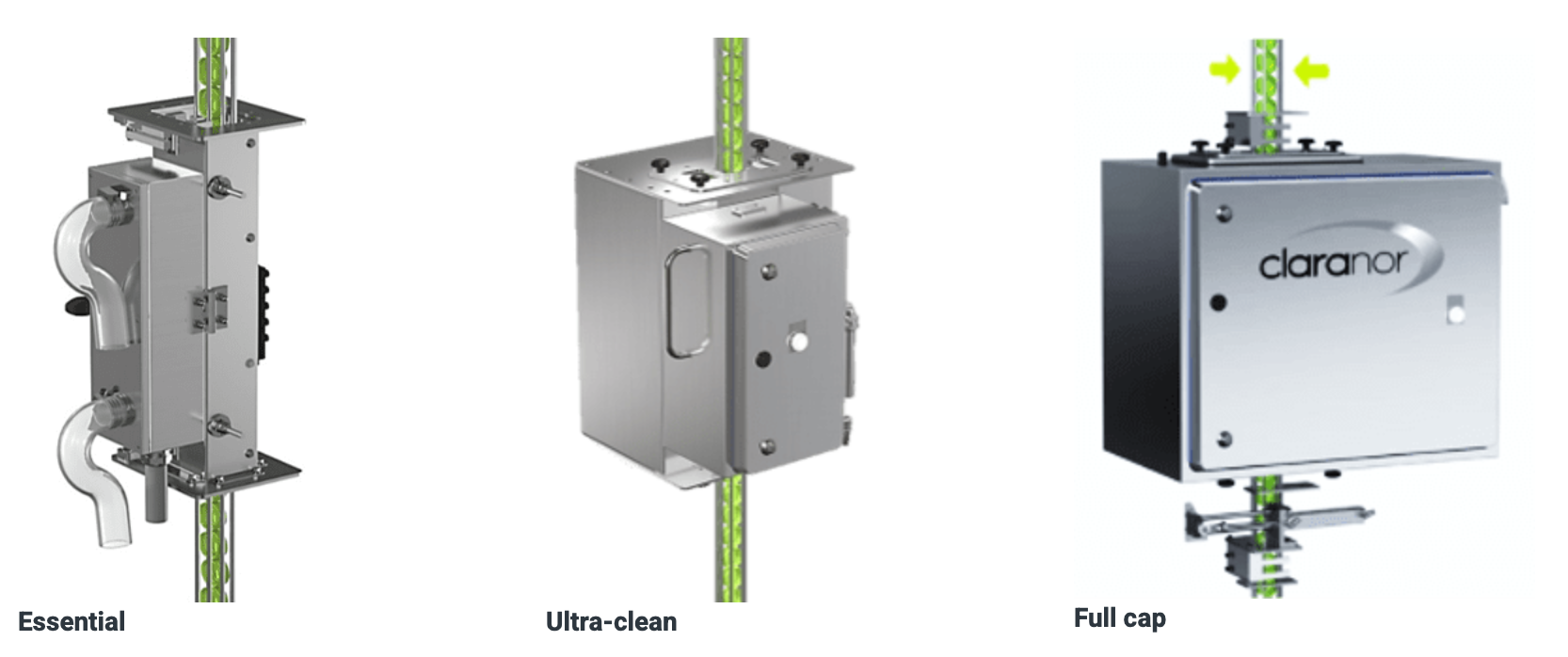

Claranor pulsed light is a non-chemical and athermal surface process. It respects the quality of all types of material: PS, PP, PE, and metal caps, with or without aluminum seal. On caps with a lid, it avoids the risk of chemical product residues under the lid.

Standards and materials

The standards for packaging, in this case, caps, aim to reduce plastic pollution. By 2024, all plastic bottle caps will have to be attached to their bottle (up to 3L). In other words, all the caps must remain on the bottle, and the consumer must be able to open and use his product without having a loose cap, that he can lose, or that can be found more easily in nature.

This concept will become compulsory for all plastic bottles, including sparkling water bottles, which cannot benefit from this innovation at present because of the need for the necessary progressive degassing.

With regard to the materials used, there are too many current and future standards that encourage manufacturers and therefore consumers to favor eco-responsible and/or sustainable packaging.

The EU is launching the race for “eco-design” and is therefore insisting that manufacturers make it compulsory to include recycled PET in bottles up to 25% by 2025 and 30% by 2030.

In a movement of circular economy, budgets are even allocated to enable manufacturers to promote this ecodesign and encourage innovation in this direction.

There are many benefits of packaging decontamination using pulsed light in the beverage sector: sterilization without chemicals and risks of chemical residues, reduction or elimination of ozone in water. The possibility to reduce or eliminate the use of preservatives for example.

- In Water Bottle

- In Beverage Industry

- In Dairy Products