Despite widespread disruption, ACG is continuing production in its factories around the world, helping to keep supply chains running smoothly to meet mission-critical demands. Being a crucial supplier to the pharmaceutical industry in these difficult times comes with a huge duty to care for employees and associates, and ACG continues to do ‘everything and more’ to protect their safety and wellbeing.

ACG provides dosage capsules and high-barrier blister packaging films for all specifications, as well as advanced machinery and technical support for pharmaceutical facilities. All ACG Capsule and ACG Films & Foils factories around the globe are currently running at full capacity, and all orders are being fulfilled.

Of course, employee safety remains a primary concern for ACG during this time, with strict, comprehensive COVID-19 precautionary measures in place at ACG factories across India, Europe and Brazil to ensure the continued health and safety of all ACG associates.

At plant level, measures comprise daily sanitizing of factory premises and property, including common areas, offices and vehicles – plus strict social distancing rules, employee screening, sanitizer dispensers throughout factories, awareness sessions from medical professionals, and full access to personal protective equipment (PPE). Such steps are reviewed and updated continuously to align with expert health advice and policy.

To encourage higher hygiene and safety standards, ACG factory shifts are currently 12 hours, to support social distancing measures and reduce travel between factories and communities. ACG has also arranged medically equipped isolation facilities, and provides worker accommodation at selected sites.

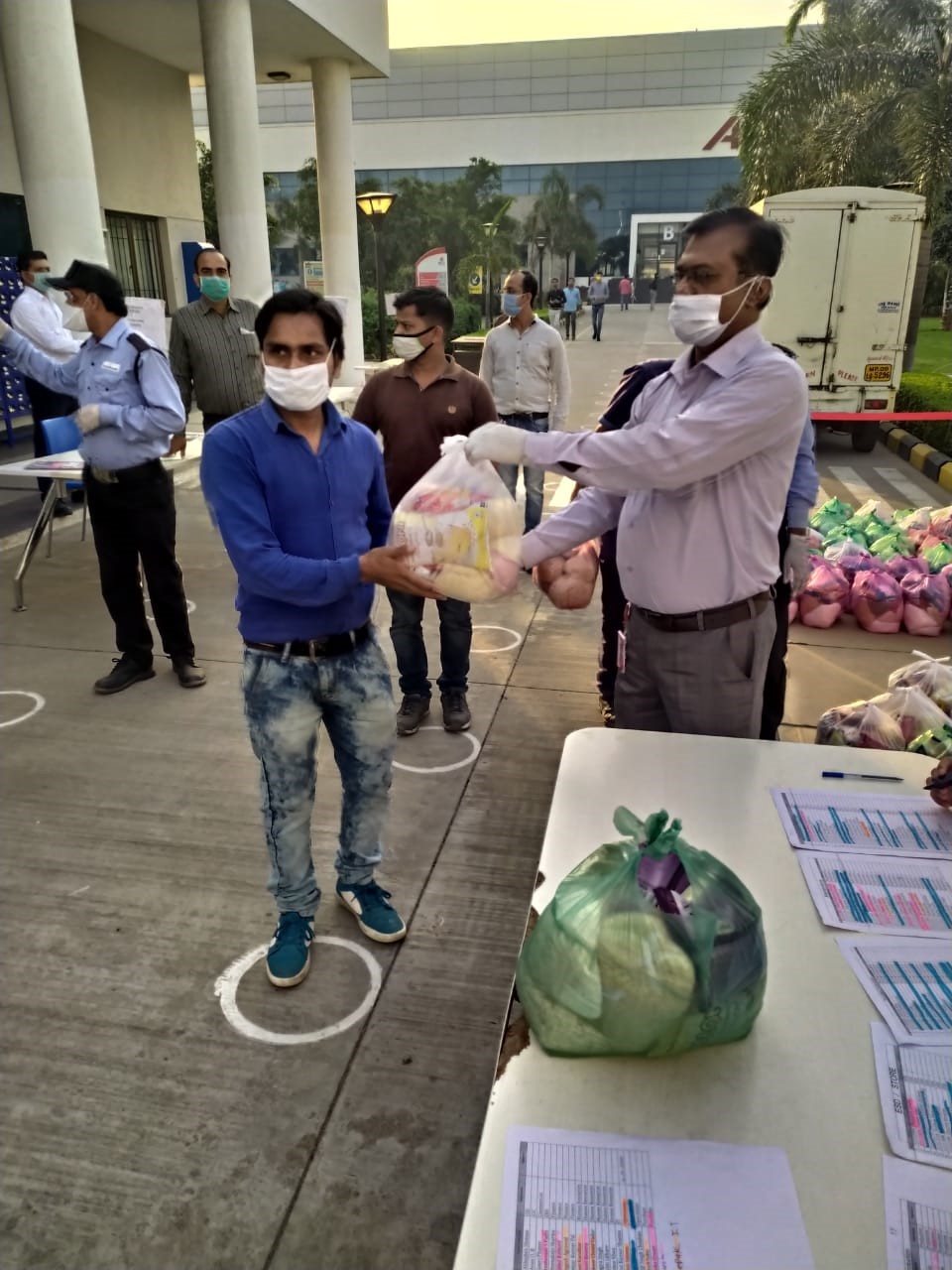

In ‘lockdown’ countries, ACG continues to provide workers with ready-packed vegetables, groceries and sanitation kits to take home to their families. Meanwhile, for safer commuting between home and work, ACG has arranged special vehicles that are sanitized before and after every journey. In India, ACG has also given an additional insurance cover of INR 200,000 (over and above the existing policies), insuring all its employees and their families against medical expenses that may occur this year.

Every ACG plant worldwide has a contingency plan and Standard Operating Procedure for suspected or confirmed cases, and for quarantine.

Additional measures for product transportation

To ensure ACG products and equipment reach customers on time, ACG has been working closely with local government officials to keep manufacturing supply chains as open and efficient as possible. This includes sourcing, securing and distributing everything from gelatin to food colouring and additives, to packaging materials, and more.

ACG Capsules and ACG Films & Foils are classified as ‘Essentials’ by government authorities, so delivery vehicles owned by ACG and its suppliers are ensured safe and smooth transit between key supply-chain locations.

On taking extraordinary safety measures for the ACG workforce, Mr. Sunil Jha, Group CHRO, said,

“People are our first concern – our associates, suppliers, partners, customers, and end-users. All efforts at ACG are dedicated to helping make people, and the world, healthier. It may be our business, but right now it's also about so much more. We salute the spirit of our employees who are coming to work every day and doing their bit in fighting the COVID-19 virus. ACG stands with them."

About ACG

ACG has been providing innovative and integrated solutions to the global pharmaceutical and nutraceutical industries for almost 60 years, in over 100 countries across six continents. ACG products include capsules, film and foil barriers, and engineering equipment and inspection systems. All comply fully with international regulatory requirements.

For more information, please contact the ACG media relations team:

Tanya Grover: tanya.grover@acg-world.com

Madhurima Chakraborty: madhurima.chakraborty@acg-world.com

ACG media relations team