Amcor’s upcoming exhibit – booth C11743 - at the International Production and Processing Expo (IPPE) January 24 – 26 in Atlanta, Ga. will welcome visitors with a broad display of retail packaging solutions and daily in-booth demonstrations of a fully integrated, production-ready fresh protein packaging line.

"I’m excited about IPPE this year, because Amcor will give customers a first-hand opportunity to see how our industry-leading packaging solutions Eco-Tite®, CBP®, ABP® and Flow-Tite® are paired with best-in-class packaging equipment and exciting new automation technologies. This brings significant opportunities to protein processors to reduce total packaging spend and dramatically reduce their packing and pack-off labor," said Scott Fallon, vice president and general manager of Amcor Flexibles North America. "We know that to optimize our customers packaging, we need to integrate the best film technology, the very best packaging equipment and cutting-edge automation technologies and that’s exactly what we are bringing to IPPE."

Paired with many decades of Amcor’s leading packaging solutions, Amcor will highlight operational efficiency opportunities to reduce total packaging spend, improve safety, and decrease labor. Demonstrating this will include:

- Moda vacuum packaging solutions have engineered a best-in-class system for vacuum packaging that endures the challenges of demanding environments and increases productivity. The Moda system will include Moda Pac, Moda Vac, and Moda Bag.

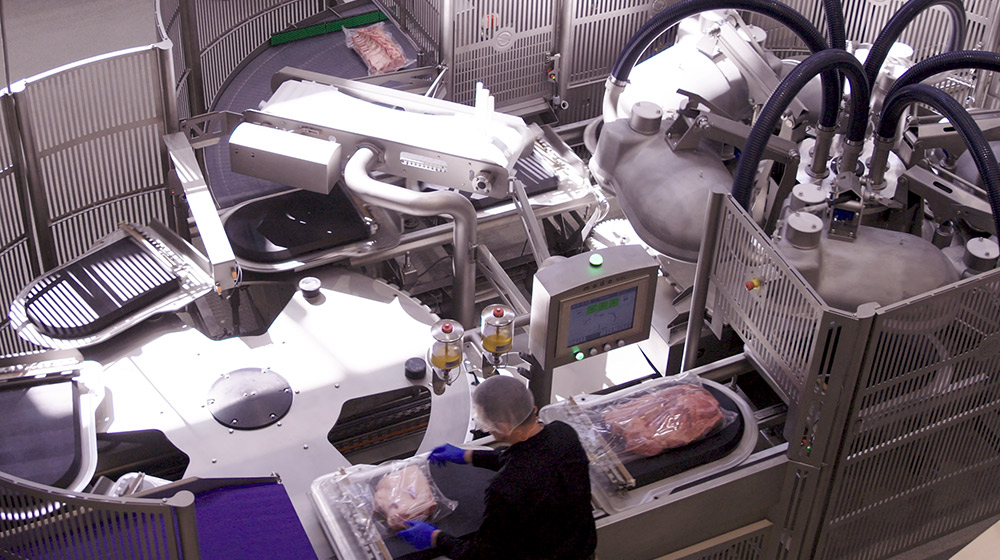

- The innovative rotary vacuum chamber system – Moda Pac - is unmatched in ease of use to operate, connect, clean and maintain. With automated rollstock loading using Amcor films and bags as an alternative to traditional boxed bags, processors can decrease labor requirements and packaging spend.

- The on-demand tube-to-bag system allows bags to be made using only what is needed and greatly reduces packaging SKUs, spend, working capital and warehouse space.

- Marble Technologies develops intelligent automation solutions to address labor-intensive, repetitive, and difficult processing tasks. At IPPE, Marble will be displaying its automated vision system.

- The automated vision system is fully integrated with the packaging line and identifies, weighs, and inspects meat products at production rates. This provides access to real-time production data. Marble’s breakthrough technology is key to effectively automating tasks in fresh meat processing.

"Marble is excited to demonstrate its automated vision system at IPPE. Technology has rapidly advanced in recent years, which has made it possible to automate tasks once thought to be impossible. Marble is leading the way in bringing next-generation automation technology to meat processing facilities," said Chafik Barbar, CEO of Marble Technologies.

Protein processors can also leverage Amcor’s innovative packaging to connect with consumers. The booth will showcase case-ready offerings, print and finishing technologies that help brands stand out, and deliver more sustainable solutions backed by life cycle assessment metrics.

- Amcor’s ASSET™ life cycle assessment service, third party certified by the Carbon Trust, offers an interactive tool that assists with data-driven decision making for customers facing sustainability choices. The service will be displayed on large touchscreens and includes over 130 simple life cycle assessments that compare a non-sustainable common package with one of Amcor’s more sustainable alternatives. The results provided by the program include quantitative metrics that measure the change in carbon footprint, energy and water consumption.

- The Amplify® experience allows the attendee to select a specific need for their package to deliver on shelf, such as organic and natural cues, and then suggests one or more print and finishing technologies that provides those benefits.

- The retail fragmentation overview is another interactive program in which the visitor selects one of six channels to learn about their unique challenges and optimize the packaging for various channel-specific complexities such as lighting, shelf-sets, and logistics.

Daily demonstrations of packaging equipment and film in Amcor’s booth C11743:

- Tuesday, January 24: 10:00 am and 2:00 pm

- Wednesday, January 25: 10:00 am and 2:00 pm

- Thursday, January 26: 10:00 am and 12:00 pm

To learn more about Amcor’s protein packaging solutions, visit us at www.amcor.com/products/food/meat-fish-seafood/na.

For more information:

Mary Johnson, Director Marketing Communications

Amcor Flexibles North America

+1 920.527.5134 | mary.johnson@amcor.com

About Amcor

Amcor is a global leader in developing and producing responsible packaging solutions for food, beverage, pharmaceutical, medical, home- and personal-care, and other products. Amcor works with leading companies around the world to protect their products and the people who rely on them, differentiate brands, and improve supply chains through a range of flexible and rigid packaging, specialty cartons, closures, and services. The company is focused on making packaging that is increasingly lighter weight, recyclable and reusable, and made using an increasing amount of recycled content. In fiscal year 2022, 44,000 Amcor people generated $15 billion in annual sales from operations that span 220 locations in 43 countries. NYSE: AMCR; ASX: AMC

About Moda

High performance Moda packaging systems have been crafted to endure the challenges of demanding environments, increase productivity across the board, and provide energy, labor costs and packaging material savings for your business. Ergonomics, product-flow and hygiene are always at the forefront of our design brief. The end result is a rigorously tested and highly effective line up of modular systems that work together to provide outcomes never seen before.

www.modanz.com

About Marble Technologies

Marble Technologies develops intelligent automation to revolutionize the way food is processed. Starting in meat processing facilities, Marble brings together advanced software, artificial intelligence, computer vision, and robotics with state-of-the-art hardware design to automate labor-intensive, repetitive, and difficult tasks.