CEFLEX, the collaborative initiative to increase the collection and recycling of flexible packaging formats below A4 in size, has grown dramatically since its official launch in 2017 at Interpack. The number of participating stakeholders has risen by 56% in the past seven months to reach 53, with companies and organisations from across the value chain.

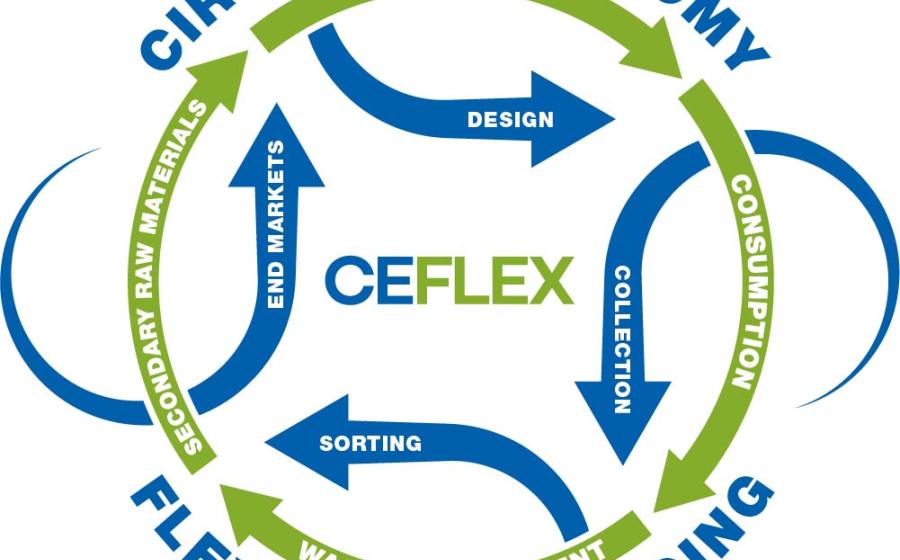

CEFLEX’s ambitions are to make flexible packaging more relevant to the circular economy by advancing better system design solutions via collaboration of stakeholders representing the entire value chain, by 2025. “Thanks to the significant number and broad base of stakeholders, plus strong collaboration, progress is being made in all workstreams. The newly released Plastics Strategy further underlines the relevance of the work CEFLEX is doing.” explained Graham Houlder, the project coordinator.

The initiative is focused on consumer flexible packaging formats, which can be either single or multi-layer, use a variety of materials and which are not widely collected today for recycling in Europe. According to Thomas Greigeritsch of Constantia Flexibles, a leading global flexible packaging converter: “Flexible packaging is highly material efficient, only generating a limited amount of waste at its end of life but, if the waste is not collected it cannot be sorted and recycled.”

“There is a clear need to increase collection initiatives and to raise awareness that a large fraction of this post-consumer waste stream is ready for recycling today. In a circular economy, we cannot simply send that valuable material to landfill or energy recovery instead of recycling it. This is one of the first areas of focus for CEFLEX,” he added.

Secondly, CEFLEX aims to help improve the recyclability of flexible packaging. Work on the development of the first phase of Design for a Circular Economy Guidelines for flexible packaging formats below A4 is underway, with valuable insights captured from the stakeholders. The first draft of the Design Guidelines will be launched for public consultation in spring 2018. Kevin Vyse of Marks & Spencer (UK) confirms that these are a key element to increase recycling of flexible packaging materials. “We (M&S) expect both economic and environmental advantages from designing flexible packaging which is easier to recycle.”

In addition, CEFLEX stakeholders are working together to identify and promote the best solutions to increase the recycling of flexible packaging in a circular economy. Michael Heyde of DSD (Germany) explains: “Projects are being planned to help us identify the most promising technical developments to effectively and economically sort and recycle post-consumer flexible packaging. We will then validate these through a robust programme of trials and pilots. The aim is to find and implement practical and scalable solutions more quickly.”

Graham Houlder wants to see rapid progress but recognises that this will need broad support from society in general: “Our goal is to get commitment and buy-in from the whole value chain including local authorities and regulators. This is essential to ensure the broad-based adoption and implementation of what we are developing for flexible packaging in a circular economy.”