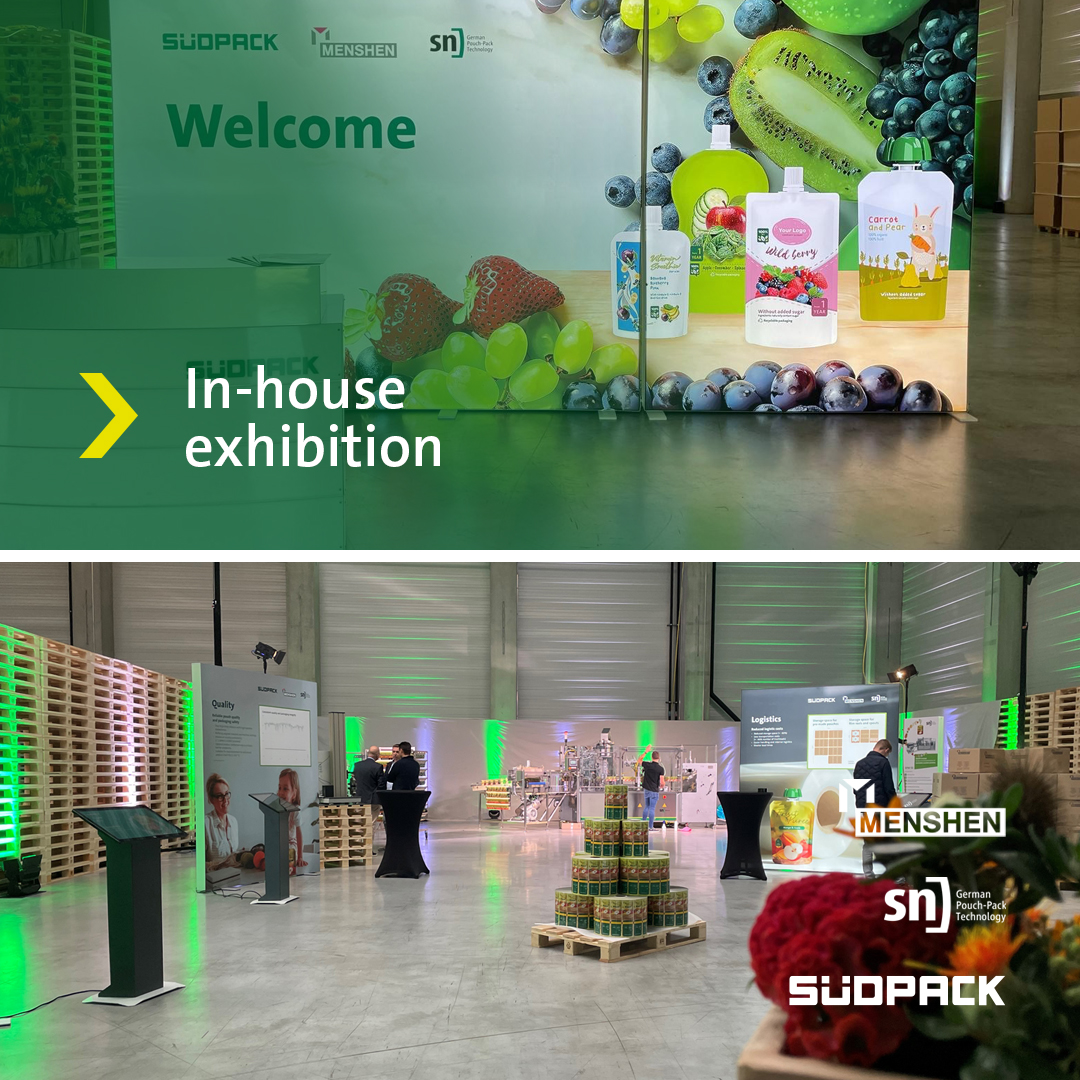

SÜDPACK, SN Maschinenbau, and Menshen welcomed customers and media representatives to SÜDPACK’s Erolzheim site for an engaging live event. The spotlight was on a cost-efficient and highly sustainable end-to-end solution for the in-house production of spouted pouches for packaging liquid and pasty food products. The unanimous verdict among those present: The new solution is a strong overall concept with real added value.

At four different themed stations, SÜDPACK’s customers and members of the media had the chance to explore four key focus areas: economic profitability, logistics, quality, and sustainability. Live demonstrations followed, allowing the guests to experience the new concept’s many advantages firsthand. On both days, experts from all three partners were available for exclusive one-on-one discussions.

The innovative new solution …

enables flexible, highly efficient in-house production of spouted pouches in various sizes and shapes, including the processing of different spout types. At its core is the high-performance SPM 50 packaging machine from SN Maschi-nenbau, which works seamlessly with mono-materials. The PP-based – and therefore recyclable – high-performance films for pouch production are pro-vided by SÜDPACK, while the corresponding spouts come from Menshen. The materials and machine settings are perfectly aligned, achieving optimal packag-ing results with maximum tightness and burst-pressure resistance. “Through our development partnership, we have created a turnkey solution that cus-tomers can implement quickly and without complications – and it’s a trailblazer in terms of sustainability and economic profitability,” explains Valeska Haux, Vice President Strategic Marketing & Sustainability at SÜDPACK.

Cost-effective, efficient, easy to handle

Manufacturers and packaging companies that process fruit purees, smoothies, and other liquid or pasty foods requiring thermal treatment after filling will benefit from these advantages. By producing pouches from roll stock material and using spouts delivered in cardboard boxes, material costs can potentially be cut in half, while logistics and handling expenses are also significantly re-duced. As a result, the initial investment in the pouch-making machine can be amortized relatively quickly. Nils Hembach from SN Maschinenbau explains: “Typically, with an output of 4,200 pouches per hour, the film reel only needs to be changed once per shift – a huge advantage compared to handling pre-made pouches. Our customers also benefit from maximum flexibility in terms of pouch formats.”

The key advantage: sustainability

A quick glance at the CO2 emissions highlights the benefits: For 260,000 pouch-es transported over 100 kilometers, emissions are nearly halved – from just under 21 kg to 10.4 kg of CO2. The new packaging concept, consisting of SÜD-PACK’s extremely material-efficient, PP-based high-performance films, and Menshen’s PP- and PE-based spouts, has been certified as 96% recyclable by the independent institute cyclos-HTP. “We’re breaking new ground and proving that Design-for-Sustainability is possible, even for practical spouted pouches,” says Valeska Haux from SÜDPACK.

The synergy between the components results in packaging that provides opti-mal product protection, thanks to its excellent sealing performance – a crucial aspect in terms of product safety and combating food waste. Eric Dauer, Sales Manager from Menshen adds that a high level of packaging reliability is also ensured because “the spouts, available in various designs, can be securely in-tegrated into the pouches.”

Concrete facts

To back their claims, the experts from the three partner companies provided robust analysis data and credible forecasts for the attending guests. “With our EcoTrace™ LCA service, we can assess the environmental impact of a holistic packaging concept or high-performance films and, if required, provide ISO cer-tification,” explains Valeska Haux from SÜDPACK. Menshen and SN Maschi-nenbau, in turn, focused on the operational and cost benefits of this efficient, highly flexible in-house solution, comparing it to the processing of pre-made pouches in terms of handling and logistics.

The discussions continued over traditional Swabian delicacies, providing ample opportunity for in-depth conversations on both days. The event was rounded off with a factory tour of the SÜDPACK site in Ochsenhausen. “As SÜDPACK customers, an exclusive event like this one is incredibly valuable for us,” re-marked one attendee. “Unlike at a hectic trade show, there’s plenty of time for constructive discussions and we can also outline our specific requirements.”

About SÜDPACK

SÜDPACK is a leading manufacturer of high-performance films and packaging solutions for the food, non-food and medical goods industries and also of cus-tomer-specific compounds for technically demanding applications.

The family business, which was founded by Alfred Remmele in 1964, is head-quartered in Ochsenhausen. The production sites in Germany, France, Poland, India, Switzerland, the Netherlands and the USA are equipped with cutting-edge plant technology and manufacture to the highest standards, including the capacity to operate under clean room conditions. The global sales and service network ensures a high degree of proximity to the customer and comprehen-sive application technology support in more than 70 countries.

With its state-of-the-art Development and Application Center at its headquar-ters in Ochsenhausen, the innovation-oriented company offers its customers an optimal platform for developing individual and tailor-made solutions and also for performing application tests.

SÜDPACK is committed to sustainable development and fulfills its responsibility as an employer and towards society, the environment and its customers. For its sustainable product developments and consistent commitment to a func-tioning circular economy in the plastics industry, SÜDPACK has received nu-merous awards.

About SN Maschinenbau

As one of the world’s leading manufacturers of pouch packaging machines, SN Maschinenbau stands for high-quality and custom-made horizontally operating form, fill and seal machines (HFFS) as well as fill and seal machines (HFS) – Made in Germany. At the company site in Wipperfuerth near Cologne, approx-imately 300 employees develop customized packaging machines for the food, pet food and seed industries as well as for household, cosmetic and pharma-ceutical products. SN is valued internationally by both large corporations and SMEs for the quality of its machines and packaging technology and can be found in nearly all renowned establishments. Further information is available at www.sn-maschinenbau.com

About Georg MENSHEN GmbH & Co. KG

The owner-managed, medium-sized family company is located in Finnentrop in the Sauerland region of Germany and is a global manufacturer of closures, plastic solutions and packaging systems. For more than 50 years, MENSHEN has been pioneering in the development, production and further processing of plastic closures and packaging systems. The company collaborates with strate-gic partners in the cosmetics, chemical, cleaning and food industries as well as in the packaging industry, in this case with SÜDPACK and SN Maschinenbau.

In addition to a competence center for special machinery and assembly and innovation centers for various closure solutions, the company has additional production facilities and subsidiaries in Switzerland, the UK, France, Spain, the USA, Mexico, Singapore, China, Columbia and Serbia. MENSHEN employs ap-proximately 1,600 people worldwide, around 300 of whom are located in Sau-erland. More information is available at www.menshen.com