Live again at last, Reifenhäuser will exhibit at Fakuma in Friedrichshafen from October 12 to 16, 2021. It is the first major presence event for the plastics industry to take place in Germany this year.

The Reifenhäuser Group is represented on a joint exhibition booth (A6- 6206) by its three business units, "Reifenhäuser Extrusion Systems", including the screws and barrels specialist "Reifenhäuser Reiloy", along with its film divisions "Reifenhäuser Blown Film" and "Reifenhäuser Cast Sheet Coating". The divisions will exhibit their broad portfolio of plasticizing components for injection molding and extrusion together with complete lines for blown film and flat film production.

Wear-resistant components for recyclate processing The focus of this year's Fakuma is clearly on the change from a linear to a circular economy and the resulting new demands that this places on components and production lines. Ralf Pampus, Managing Director of Reifenhäuser Reiloy, explains: "In recyclate processing, the extruder plays a particularly vital role since recyclate quality often varies and impurities or wear-inducing substances must be safely processed. This is why we offer our customers highly wear-resistant screws and barrels. In fact, we are the only manufacturer that develops and produces hard-metal alloys for wear protection in-house. This helps us to achieves extremely long service life - a crucial factor affecting the economic efficiency of production lines."

Reifenhäuser regularly sets benchmarks in wear protection with its wellknown Reiloy screws and barrels, offering verifiably longer service life, precise matching of raw materials and additives, and exclusive alloys with powders developed in-house and process-optimized surfaces. Manufacturers of injection molding and extrusion products therefore benefit from the best cost-benefit ratio in the industry.

Sustainable cast film for the circular economy "Reifenhäuser Cast Sheet Coating" presents complete line concepts for flat film production. The trade show highlight is the new MIDEX 11-2500 Cast Film Line with MDO, which Reifenhäuser has now put into service at its film Technology Center located at its headquarters in Troisdorf. The line is a genuine all-rounder and has an impressive range of applications. Customers can produce a wide variety of products on it, from CPP and CPE films to barrier, hygiene, and industrial films. This helps to react flexibly to rapidly changing market requirements. Mark Borutta, Sales and Marketing Manager at Reifenhäuser Cast Sheet Coating, says: "This line supports our customers to further develop their products; for example, they can offer sustainable end products by downgauging and changing from conventional multimaterial barrier films to monofilms.”

Sustainable cast film for the circular economy "Reifenhäuser Cast Sheet Coating" presents complete line concepts for flat film production. The trade show highlight is the new MIDEX 11-2500 Cast Film Line with MDO, which Reifenhäuser has now put into service at its film Technology Center located at its headquarters in Troisdorf. The line is a genuine all-rounder and has an impressive range of applications. Customers can produce a wide variety of products on it, from CPP and CPE films to barrier, hygiene, and industrial films. This helps to react flexibly to rapidly changing market requirements. Mark Borutta, Sales and Marketing Manager at Reifenhäuser Cast Sheet Coating, says: "This line supports our customers to further develop their products; for example, they can offer sustainable end products by downgauging and changing from conventional multimaterial barrier films to monofilms.”

The special feature here: Visitors can inspect the line virtually at the Fakuma booth. Reifenhäuser has digitized its entire film development Technology Center, offering its customers a guided 360° tour on a large screen at the trade show. The MIDEX 11-2500 is also now available at the Reifenhäuser Technology Center for customer trials and joint product development.

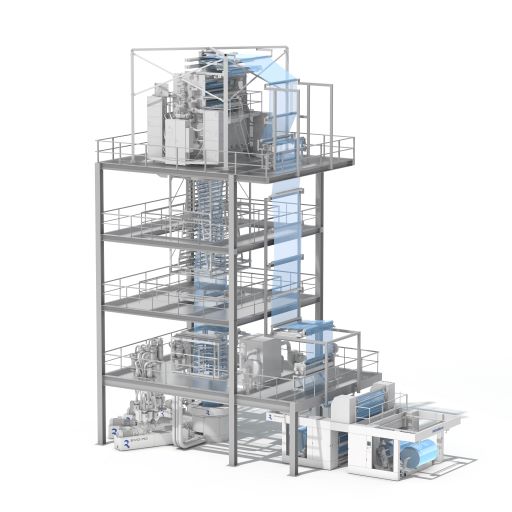

Ultra Stretch: Innovative stretching process enables All-PE composite for flexible packaging The third business unit, Reifenhäuser Blown Film, will also focus on its capability of producing recyclable end products. The technology solution here is EVO Ultra Stretch - Reifenhäuser's highly advanced stretching unit for sustainable blown films. It allows customers to produce monomaterial composites (All-PE film) for flexible packaging. The regular PET layer is replaced by stretched PE. With up to 10 times the stretch rate, the Ultra Stretch unit gives PE film completely new mechanical properties. This is a simple substitute for PET and there is no need to adapt other processing steps. The unique and patented position of the stretching unit directly in the haul-off of the blown film line makes the process particularly stable and efficient. Eugen Friedel, Sales Director at Reifenhäuser Blown Film, explains: "The special feature about our solution is that we stretch the film when is still hot from extrusion, at just the right time, and without having to reheat it. This also extends the natural annealing phase until the film is wound. It gives the film the time it needs to take on its new properties." The Ultra Stretch process is unique on the market and offers major advantages compared with the conventional process that involves stretching the film between the haul-off and the winder.

Visitors to the exhibition booth can experience Ultra Stretch technology in an impressive 3D animation video and in a virtual 360° tour through the Reifenhäuser Technology Center.

About the Reifenhäuser Group

The Reifenhäuser Group is the leading provider of innovative technologies and components for plastics extrusion. Founded in 1911, the company delivers advanced solutions to customers around the world through its highly specialized business units. With its technologies and the know-how of its 1,750 employees, Reifenhäuser has the world's largest network of expertise in plastics extrusion technologies. The CEO of the Group is Bernd Reifenhäuser