Sacmi will be at the 13th edition of Anutec (27-29 September 2018) – a key platform on the strategic Indian market – to showcase everything from the FFS packaging machine range for the food industry to its integrated PET production range with comprehensive pellet-to-pallet solutions.

Sacmi’s complete beverage plants are set to play a starring role at Anutec, the food&drink processing fair being held in Mumbai from 27 to 29 September 2018 (Bombai Exhibition Centre). The success of the previous 12 editions underscores just how important this event is for India, a market that is nothing less than strategic for Sacmi machines and complete lines.

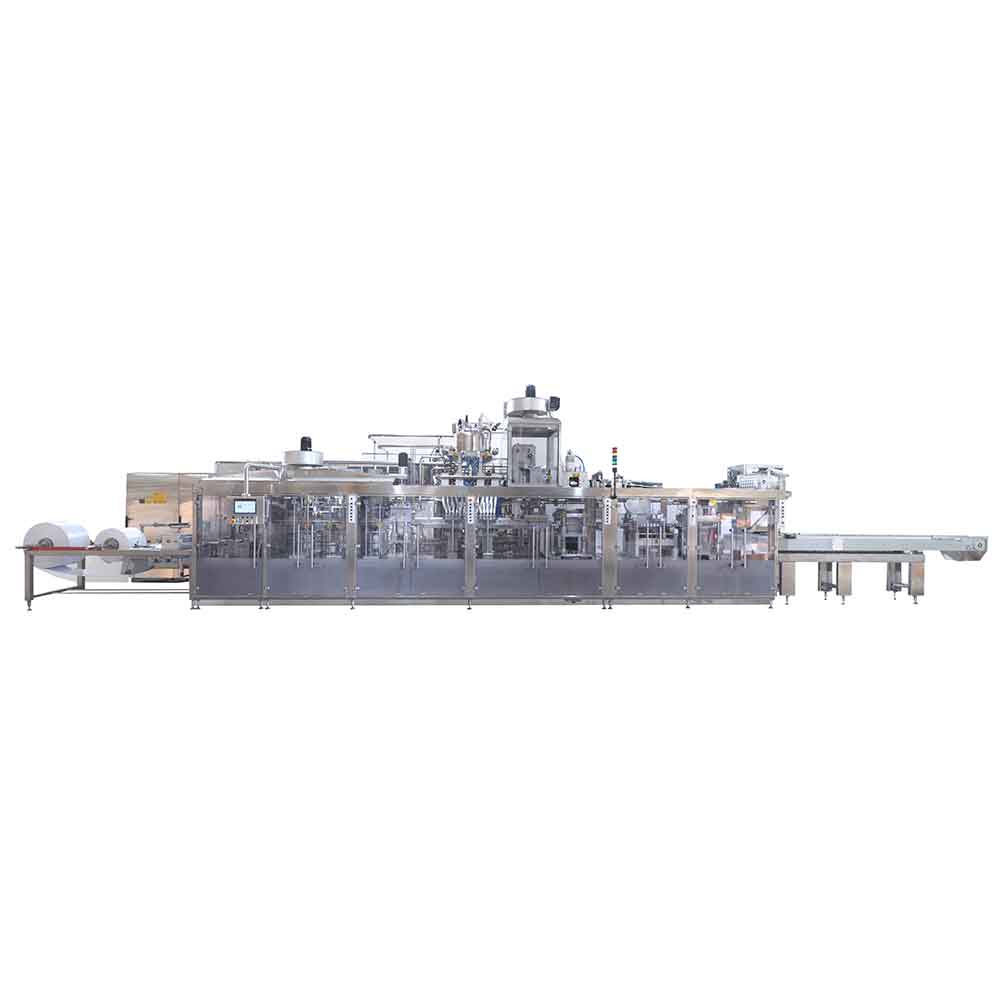

The Group stand (hall 1, booth C32) will be placing considerable emphasis on complete FFS solutions. Developed by Sacmi Beverage, a Sacmi Group company owning trade mark Benco Pack with over 50 years’ experience in the industry, form-fill-seal horizontal packagers for the food industry come in a wide range of configurations. Available in aseptic and non-aseptic versions, their output rates span from 6,000 to 100,000 containers per hour and cover sizes from 10 to 250 ml. More specifically, Sacmi recently developed and presented a smart version of the solution, a horizontal 6,000 cph packager for dairy products.

Being able to provide packaging machines with the Sacmi shrink sleeve application device in multi-pack configurations (patented Sacmi ISA, integrated sleeve applicator) gives the final product added value, rewarding producers with new individual brand marketing and enhancement opportunities and allowing the development of new product lines at competitive cost. Moreover, Sacmi Beverage has a reputation for supporting customers closely right from the design stage; for example, we provide consultation for the manufacture of containers with new shapes in order to achieve the best balance between eye-catching design and optimisation of raw material consumption and costs.

One of just a handful of competitors in the world capable of developing a comprehensive range for every phase of the beverage production line, Sacmi is, at this latest edition of this Indian fair, set to strengthen its role as an all-round plant engineering provider thanks to cap and preform production solutions integrated with the downstream bottling line. The heart of the new Sacmi HeroLine is Heroblock, the all-in-one quadblock that combines the blowing, filling, capping and bottle labelling stages.

Contained consumption, logistic efficiency thanks to less handling and improved final product quality are but some of the advantages of the HERO configuration. Extensive technological expertise covering every stage of the process lets Sacmi design the optimal plant configuration – with modular, flexible pellet-to-pallet solutions – together with customers according to their specific production requirements.

Sacmi doesn’t just provide technological excellence: manufacturing and sales companies operate worldwide to ensure far-reaching customer service. Sacmi Engineering, a one-stop production, sales and assistance reference point serving the entire Indian market, is a case in point. Lastly, all projects receive close support from the Sacmi Beverage laboratory, a facility certified by the global industry’s biggest players.