In the third quarter of fiscal year 2024, UFlex Limited introduced a multitude of innovative products across its business verticals. The company also achieved notable recognition by winning multiple awards and securing patents in the quarter ended December 31, 2023.

Packaging Films Business

1. B-INM-M, Superior Barrier Metallized BOPP Film: This film stands out as a premier choice for various packaging needs. Inline-coated and metallised, it offers an exceptional oxygen barrier (OTR) of less than 01 cc/m2/day and boasts an excellent moisture barrier (WVTR) of less than 0.1 g/m2/day. With superior metal bond strength and cost-effective attributes, it is engineered for recyclability. This versatile film finds its application in a multitude of sectors including dry beverages, chips and snacks, health and beauty care sachets, detergents, and confectionery products. Its triple structure versatility allows it to replace aluminum foil and metallized PET, offering convenience and efficiency. It caters to diverse packaging requirements, ranging from 2-ply extrusion applications to single-layer pouches and sachets. The film includes features like both-side treatment and one side for metallization; hybrid composition with one side emphasizing high heat seal strength and the other side for metallization, and thicker micron options (30/40) with one side low SIT and the other side for metallization, making it an indispensable solution for a wide array of packaging applications.

2. C-CPM-ML-M, CPP metallized film: This film is tailored specifically for molasses packing, constituting a functional raw material that excels in various aspects. Recognized for its good seal integrity, this film ensures that contents remain securely enclosed, preserving freshness and quality. Boasting commendable barrier properties, it shields against external elements, maintaining the integrity of the packaged molasses. Its exceptional hot tack facilitates efficient sealing processes, enhancing productivity and reliability. Moreover, the film exhibits good metal adhesion.

3. The C-CBP-WG CPP film: This film stands as a functional raw material designed to meet stringent packaging demands. Renowned for its exceptional optical properties, this film ensures clear visibility and presentation of packaged goods, enhancing product appeal. With low slip characteristics tailored for high-speed packaging environments, it ensures smooth handling and reliable performance throughout the packaging process. Notably, it boasts excellent drop impact strength, providing robust protection against potential damage during handling and transportation. Primarily engineered for low ambient temperature conditions, this film finds its niche in bread packaging, frozen foods, and bakery products, where maintaining product quality and integrity is paramount. Its versatility makes it a preferred choice for businesses seeking packaging solutions that combine performance and practicality.

4. The B-UTX ultra high barrier Alox BOPP film: This film is a top-tier Alox-coated product crafted from BOPP, serving as a functional raw material in the packaging industry. Renowned for its outstanding barrier properties, it excels in shielding contents from gases, oxygen (less than 1 cc/m2/day), and aromas, ensuring prolonged freshness and quality retention. Additionally, its exceptional moisture barrier (less than 1 gm/m2/day) effectively safeguards against humidity and moisture ingress, preserving the integrity of packaged goods. The film's superior optics contribute to clear and visually appealing packaging presentations. Notably, its clear vacuum coating enhances its functionality and versatility across various applications. Tailored for dry foods, beverage powders, chips, snacks, biscuits, cookies, and crackers packaging, it meets the diverse needs of the food industry, ensuring optimal preservation and presentation of packaged products. The B-UTX film is a testament to innovation and quality, offering a reliable solution for businesses seeking high-performance packaging materials.

5. The B-UMB-M, an outstanding barrier metallized BOPP film: This film stands at the forefront of metallized films, offering unparalleled performance and versatility. Boasting exceptional oxygen (less than 0.1 cc/m2/day) and moisture barrier (less than 0.1 gm/m2/day) properties, it ensures prolonged freshness and quality retention of packaged goods. Furthermore, its exceptional barrier to aroma and migration barrier against mineral oil enhance product protection and integrity. With excellent metal adhesion, it guarantees secure bonding and durability. This film serves as a sustainable and recyclable solution, offering a chlorine-free alternative to PVDC-coated films and replacing aluminum foil while supporting eco-friendly practices. Its ease of processing at high speeds makes it ideal for various packaging applications, including dry fruits, beverages, chips, snacks, biscuits, cookies, crackers, confectionery, and chocolate packaging. The B-UMB-M film epitomizes innovation and reliability, catering to the diverse needs of the packaging industry while upholding sustainability standards.

Chemicals Business

1. Flexcure SF “Nutri” for NPH (Nutrition, Pharma and Hygiene) applications: Flexcure SF “Nutri” series represents a new generation radical mechanism designed especially for food packaging, pharma, and hygiene applications; for a wide range of substrates like paper, paper board and Met PET board, etc. suitable for processing with all latest generation high-speed UV sheetfed offset printing machines. The inks provided are specifically designed for application on the non-food contact side of food packaging, ensuring compliance with relevant Good Manufacturing Practices (GMP) and guidelines outlined in the Technical Data Sheet (TDS). Offering outstanding printability and transfer characteristics, these inks boast superior adhesion and maintain a controlled ink-water balance even at high speeds. With excellent curing properties and high color strength coupled with minimal misting, they guarantee optimal results. Furthermore, they adhere to stringent standards, including EuPIA and Swiss ordinance guidelines, ensuring the lowest migration and odor levels. Free from harmful substances like BP, ITX, and silicon, these inks are available in a variety of colors, including process colors, white, and all base colors, catering to diverse packaging needs.

2. Flexgreen “HFS Screen” coating for all packaging applications: The Flexgreen product series represents a new generation of our LED inks and coatings for various print applications. Flexgreen “HFS Screen” coating is a free-radical chemistry-based UV LED varnish to be applied by screen printing specially designed to print on papers, cards, and cardboard. It is a highly flexible LED coating with excellent curing capabilities on automatic/semi-automatic screen-printing machines with LED lamps of wavelength 385-395 nm. Achieving high adhesion on challenging materials like PE or PP laminates and offset inks, this product stands out for its exceptional performance. Its cured film exhibits remarkable flexibility, allowing for precise die-cutting post-application. With outstanding foil receptivity and good resistance to nails and scratches, it ensures durability and longevity. The curing process, operating within the 385-395 nm wavelength band, is consistently excellent. Furthermore, it results in an impeccably even, smooth surface with a glossy finish, free from any odor or yellowing. Notably, this product is free from harmful substances such as BP and ITX, emphasizing its commitment to safety and quality.

3. Marine Lam Inks (water-based reverse lamination inks): Marine Lam Inks are meticulously crafted for Gravure to reverse printing applications, specifically tailored for BOPP and chemical-coated polyester films, presenting a low VOC solution aligned with the ecological demands of today's society. These inks boast exceptional characteristics, including high strength coupled with low viscosity, facilitating smooth printing operations. They excel in printability and dot transfer, ensuring precise and vivid results. Notably, they exhibit outstanding adhesion on BOPP and CC PET, along with impressive bond strength values compatible with both solvent-free and solvent-based adhesives. With low VOC content, these inks emit minimal odor, enhancing working conditions. Moreover, they enable efficient printing speeds, making them a preferred choice for diverse printing needs.

4. FLEXBON R110A / FLEXBON R110C: The product is ingeniously formulated using reverse chemistry principles, where the NCO serves both as an adhesive and a hardener, accelerating the curing process. This unique approach ensures a higher crosslinking density within the polymer, resulting in expedited curing compared to conventional methods. Notably, the adhesive demonstrates excellent run-ability, facilitated by a low quantity of NCO components that contribute to rapid primary amine decay. Its standout features include faster decay of primary aromatic amines, establishing exceptional bonds even on metalized films, and boasting impressive bond and seal strength. Furthermore, it exhibits superior wettability on challenging substrates, rendering it a cost-effective and environmentally conscious solution. Its greener chemistry, characterized by low consumption of Isocyanate, underscores its commitment to sustainability and innovation in adhesive technology.

Flexible Packaging Business

1. Peelable PE Solution: A specially engineered peelable PE solution has been developed to meet the stringent demands of the Food and Beverages industry, ensuring both leak-proof performance and easy opening functionality. This innovative solution features a structured composition comprising 12 mic PET, 12 mic Met PET and 75 mic peelable natural PE. Specifically designed to cater to the unique requirements of food packaging, this peelable PE material offers exceptional sealing properties while also allowing for effortless opening. The customer, equipped with PP trays and utilizing both 12-track and 20-track machines, benefits from the versatility and reliability of this specialized packaging solution, streamlining their production processes and ensuring product integrity throughout the supply chain.

2. Packaging for Savlon Hand wash powder: UFlex has recently forayed into the packaging of the Savlon Hand Wash Powder by ITC. The product specifications entail utilizing 12 PET/ 30 PE WHITE for packaging, ensuring high-quality and reliable containment of the hand wash powder. This collaboration underscores UFlex's commitment to providing innovative and effective packaging solutions for well-established brands.

Holography Business

1. HSF in lower gauge/ thickness – Textile grade/Graphic grade and cold foil: High gloss hot stamping foil (HSF) works great for precise applications and defined patterns in small areas. Cold foil, on the other hand, is the perfect product for large areas, such as moderate or full coverage of sheet labels, stickers and folding cartons etc. The USP of these products is their fine definition application and versatility of adhesion on various printed and lacquered surfaces at lower temperature ranges. This saves energy consumption during application. Also, this high-speed stamping foil helps users to have more productivity and save time as well as costs. Due to its lower thickness, these foils provide higher film volume thus higher coverage of the material compared to traditional products available in the market. Available in numerous colours, these competitive-cost products have created a new segment in the market that provides a win-win situation to the manufacturer/ producer and end user of the product.

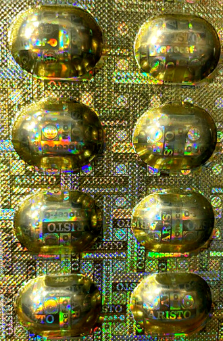

2. Holographic Alu-Alu foil for pharma: The successful commercial launch of the product — the Holographic Alu-Alu Blister marks a substantial leap forward in raising industry benchmarks in pharmaceutical packaging solutions. The Holographic Alu-Alu Blister serves as a prominent manifestation of UFlex’s steadfast commitment to pushing the boundaries within the industry in terms of Brand Protection through covert features. The introduction of the Holographic Alu-Alu Blister has undeniably created an impact on the market. This product anticipates sustained growth as pharmaceutical companies increasingly recognize the inherent value of Anti-counterfeiting solutions. The company is resolute in their commitment to innovation, ensuring that it consistently meets and exceeds the evolving needs of its esteemed clients.

Printing Cylinders Business

This business continues to manufacture cylinders compatible with sustainable inks, particularly water-based inks.

Engineering Business

1. Double Head Coating-1650: The Engineering Business of UFlex has been rising to the occasion to meet the ever-increasing demand of the market including in-house. In the recent past, there has been an increase in the demand for coating machines. The engineering business designed and developed the coating machines to cover web widths ranging up to 2500mm. One such machine of 1650mm width with double head has been supplied recently. The objective of the machines is to apply coatings spread over a range of thicknesses and carriers also. To meet the huge demand, various types of coating methods have been incorporated namely; gravure coating, reverse gravure coating with a gap, reverse gravure coating with kiss and kiss coating with a smoothing bar. Further ceramic IR heaters are very well used as preheaters before the film enters the dryer hood. In the double head coating both the heads have been made considering various demands as the first head comprises 5 drying cabinets and the second has 8 drying cabinets. Necessary safety precautions have been duly taken care of by way of using the LEL system. Additional features include floor lifting unwind and rewind, sleeve-type impression rollers, and chamber doctor blades to name a few. Riding high on the features and with the support of Corona Treaters, the machine is capable of coating right from a very thin coating of 0.2 GSM to a thick coating of 6 GSM guaranteeing smooth and even coating across the film width adding value to the substrates.

Awards and Accreditations:

• The UFlex Chemicals business has been awarded a certificate of Merit in the Dyes and Pigments Sector, by The Ministry of Power at the National Energy Conservation Awards (NECA)2023.

• The R&D lab of the Packaging Films Business known as the Testing and Research Centre (TARC) has been accredited with ISO / IEC 17025: 2017 in accordance with the National Accreditation Board for Testing and Calibration Laboratories (NABL)

Patents and Copyrights:

• The UFlex Packaging Films business has been granted a patent for its innovative research methodology to develop formable films, laminate structures, and related methods (Patent No.: 440790).

• The UFlex Packaging Films business has been granted a patent for its innovative research methodology to develop high-barrier polyethylene terephthalate film (Patent No.: 363620).

• The UFlex Packaging Films business has been granted a patent for a new innovative product, 'Monolayer PET Blister Forming Film’ (Patent No.: 473335).

• The UFlex Packaging Films business has been granted a patent for its innovative research methodology to develop formable films, laminate structures, and related methods (Patent No.: 482775).

• The UFlex Aseptic Packaging business has been granted the patent for ‘An aseptic liquid packaging container’ (Patent No.:2022/13179).

• The UFlex Engineering business has been granted copyright for ‘An ink trolley quick change over system for rotogravure printing machine station’ (Registration No.: A-148758/2023).

• The UFlex Engineering business has been granted a copyright for the innovation of an ‘Improved collar type vertical form fill seal machine with an auto splicer’ (Registration No.: A-147882/2023).

• The UFlex Engineering business has been granted copyright for an innovative product, 'Continuous motion multi-track high-speed vertical form fill seal machine (Registration No.: A-147374/2023).

About UFlex:

UFlex is India’s largest multinational flexible packaging and solutions company. Since its inception in 1985, UFlex has grown from strength to strength and has built a strong presence across all verticals of the packaging value chain - packaging films, chemicals, aseptic liquid packaging, flexible packaging, holography, engineering, and printing cylinders.

With a 10,000+ strong multicultural workforce across global regions that works toward developing innovative, value-added, and sustainable packaging solutions, the company has earned an irreproachable reputation for defining the contours of the ‘Packaging Industry’ in India and overseas. It provides end-to-end solutions to numerous Fortune 500 clients across various sectors such as FMCG, consumer product

goods, pharmaceuticals, building materials, automobiles, and more, in more than 150 countries. Headquartered in Noida, the National Capital Region, India, UFlex enjoys a global reach with advanced manufacturing facilities in India, UAE, Mexico, Egypt, USA, Poland, Russia, Nigeria, and Hungary.

A winner of various marquee global awards for product excellence, innovation, and sustainability, UFlex is the first company in the world to earn recognition at the Davos Recycle Forum in 1995 for conceptualizing the recycling of mixed plastic waste.