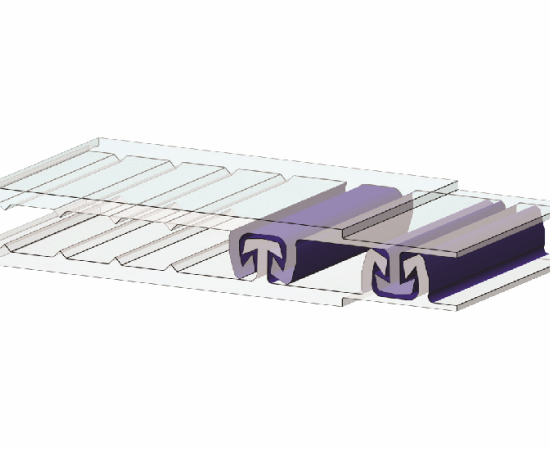

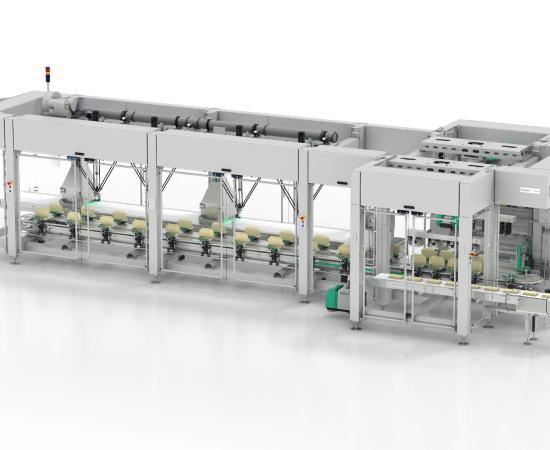

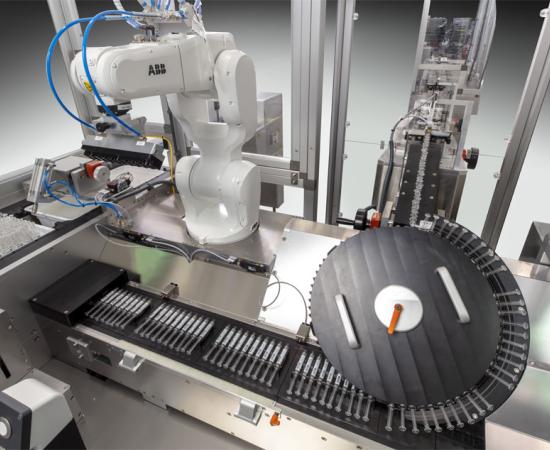

Amcor, a global leader in developing and producing a diverse offering of responsible packaging solutions, today announced the launch of a proprietary healthcare lidding technology that will be utilized for combination products – those consisting of two or more regulated components (device, drug or biologic).

- Today is: