HISTORY OF HOT STAMPING

Decorative stamping is an age-old practice used to imprint gold leaves onto surfaces, primarily to create gilded book covers. It is believed that the preliminary concept is rooted in ancient Egypt. Aa literacy increased in medieval Europe and the demand for books increased, mechanizing the process became a necessity.

Around the 1440, German goldsmith Johannes Gutenberg invented the first movable-type printing press. This creation saved artisans hours in beating gold foil into quarter-millionth of an inch in thickness.

Today, Hot foil stamping is a less painstaking process and, due to technological advancements, is more affordable as well.

By the late nineteenth century, hot stamping used heat and pressure to apply foil onto surfaces.

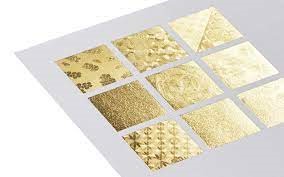

Traditionally, gold and silver metallic foils are used to provide a rich finish although any color and finish options such as glossy, matte and holographic are available on the market.

In packaging specifically, hot stamping is used to create aesthetics; rich, luxurious and elegant looks to promote brand images. It adds to the notion of value associated with the product encased in the packaging.

TYPES OF HOT STAMPING

Foil stamping can be done in two ways: traditional and digital foil stamping.

In traditional foil stamping, the design is edged onto a metal plate. Like with rubber stamping, the design of the metal plate is bonded to the surface of choice by applying pressure onto the foil through the metal plate.

In digital foil stamping, mechanical force in the form of pressure is replaced with a digital printer. This allows for different colors and designs to be printed at the same time.

According to a study by the Foil & Specialty Effects Association (FSEA), hot foil stamping and other similar enhancements on product packaging can help attract consumer attention faster and keep attention longer than ordinary packaging.