EVOH BARRIER LAMINATE

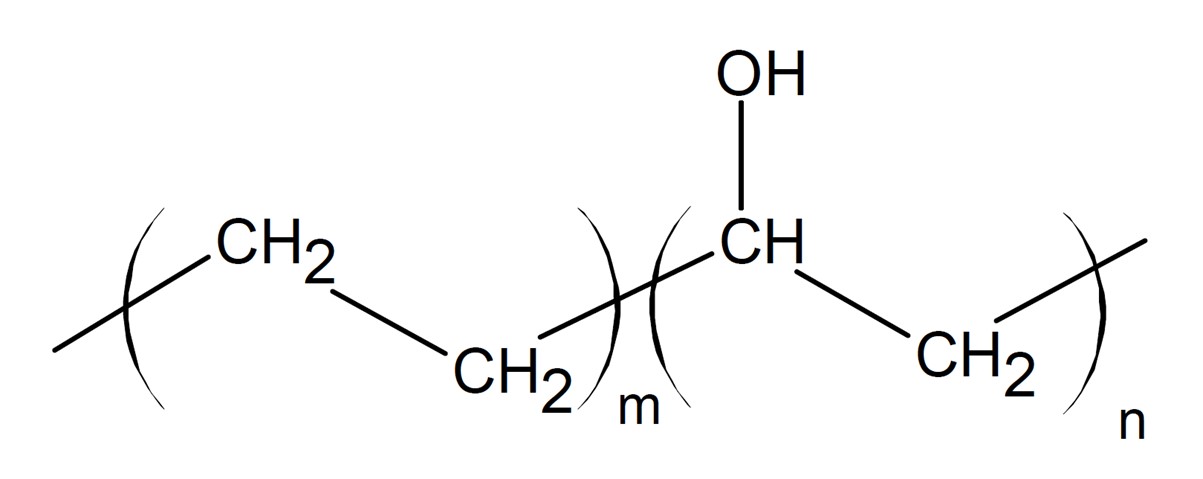

What is EVOH?

Ethylene Vinyl Alcohol, commonly abbreviated EVOH, is a formal copolymer of Ethylene & Vinyl Alcohol.

The production of EVOH contains of a two-step process of Polymerization and Saponification. First, ethylene and vinyl acetate are polymerized using an initiator/activator complex. Second, the ethylene-vinyl acetate copolymer (EVAC) is saponified to ethylene vinyl alcohol copolymer.

EVOH is used in packaging for its barrier properties against gases (O2, CO2), solvents, hydrocarbons and odours. It is also abuse, oil and dust resistant. EVOH is easily extrudable, has a glossy finish and high printability and is recyclable.

According to patent US 20020022096A1, EVOH barrier layers blended with an amorphous polyamide are highly suggested for semi-rigid packaging containers such as juice packaging.

This technology and layering of an EVOH blend with paperboard and LDPE is preferred due to its lower cost of transportation, easier disposal and lower breakage or damage probability as compared to glass containers. This packaging is also lighter in weight.

Blow moulded containers serving the same purpose are unable to prevent the loss of Vitamin C from its contents.

The trend focused on in the mentioned patent is known as “gable top”. This packaging is usually made of recyclable virgin paperboards with layered barrier laminate and is designed to look like the gable end of a house.

The patent mentions that the addition of an outer polyolefin coating provides a heat seal bond. A nylon layer coated on the paperboard helps retain Vitamin C and flavour. Flame treatment of the paperboard also helps prevent loss of oils and flavours.

Many different arrangement and treatments of LDPE, Paperboard and EVOH blends have been experimented for different liquid contents which can be further read about in the patent.

PATENT LINK: https://patentimages.storage.googleapis.com/14/26/3a/be6344760ad7f7/US20020022096A1.pdf