Near-infrared (NIR) technology is commonly used for various applications in the plastics industry, including sorting and quality control. NIR spectroscopy involves the use of near-infrared light to analyze the chemical composition and physical properties of materials. Here's how NIR technology is used for sorting in plastics:

Material Identification: NIR spectroscopy can quickly identify different types of plastics based on their chemical composition. Different plastics have distinct NIR spectra, allowing the technology to differentiate between materials like PET (polyethylene terephthalate), HDPE (high-density polyethylene), PVC (polyvinyl chloride), PP (polypropylene), and more.

Quality Control: NIR technology can assess the quality of plastic materials by measuring various properties such as moisture content, density, molecular weight, and additives. This helps ensure that only high-quality materials are used in manufacturing processes.

Contaminant Detection: NIR can also detect contaminants in plastic materials, such as foreign particles, colorants, or other impurities. This is crucial for maintaining the purity of recycled plastics or ensuring the quality of virgin materials.

Color Sorting: NIR sensors can be integrated into sorting equipment to separate plastics based on their color. This is particularly useful for recycling applications where specific colors of plastics need to be sorted for reprocessing.

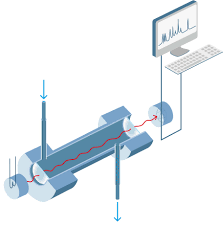

Sorting by Polymer Type: In recycling facilities, NIR technology is often used in conjunction with sorting equipment like conveyor belts and air jets. As plastic materials pass through the NIR sensors, they are quickly identified, and air jets are activated to divert them into the appropriate bins or containers based on their polymer type.

Real-Time Monitoring: NIR technology can provide real-time data on the composition and quality of plastic materials, allowing manufacturers and recycling facilities to adjust their processes as needed to maintain product consistency and quality.

Process Optimization: By continuously monitoring plastic materials, manufacturers can optimize their processes, reduce waste, and improve product quality.

Overall, NIR technology plays a vital role in sorting and quality control within the plastics industry. It enables efficient and accurate identification of plastics and helps ensure that only the desired materials are used or processed, contributing to the sustainability and cost-effectiveness of plastic production and recycling.