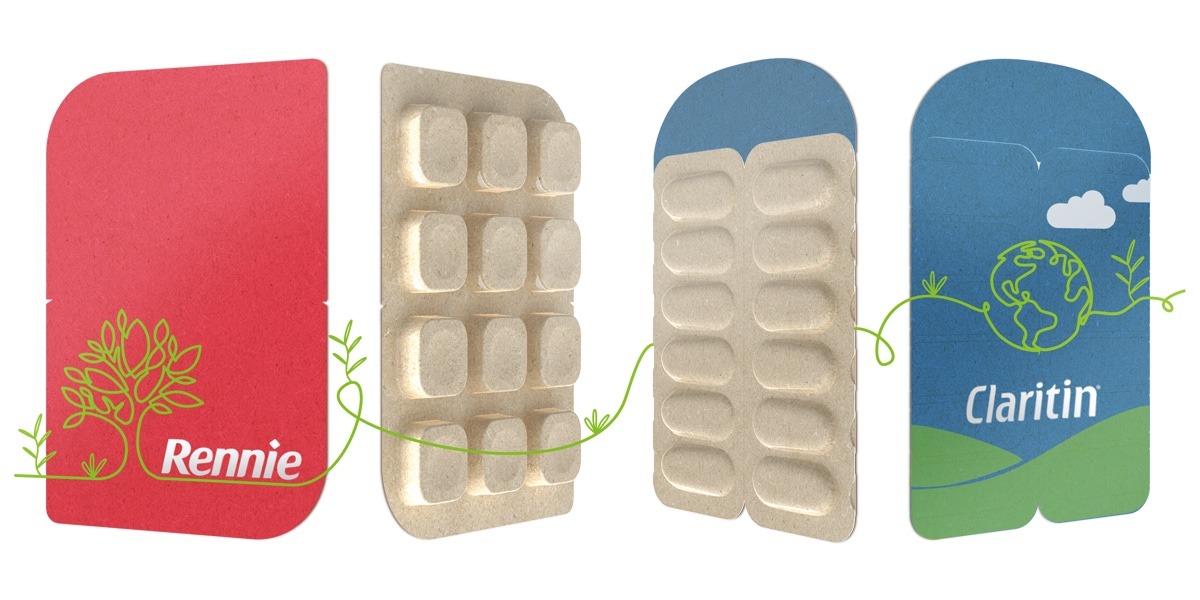

PA and PulPac have seeded the collective and developed the underlying technology needed to bring a functioning Dry Molded Fiber tablet blister pack to life. The adoption of Dry Molded Fiber tablet packs provides an opportunity to cut back on the more than 100,000 tonnes of plastic medicine packaging used every year.

Dry Molded Fiber technology minimizes CO2 emissions – leaving up to an 80% lower CO2 footprint than plastic – and requires minimal water usage. It enables the production of versatile tablet packs that are comparable to PVC packs in terms of design and tablet count.

Tony Perrotta, PulPac Partnership Lead at PA Consulting, said: “We are excited to welcome Bayer to the Blister Pack Collective. PA and PulPac formed the Blister Pack Collective to accelerate the progress to reduce single-use plastics, especially problem plastics like PVC, in over-the-counter, prescription drugs, nutraceuticals, and confectionary items. We are delighted to join forces with leading brand partners like Bayer to accelerate development and create a global impact.”

Sanna Fager, Chief Commercial Officer at PulPac, said: “Collaborations between changemakers to develop more sustainable solutions are truly powerful – and much needed. Working together, we can move toward new innovative fiber-based packaging solutions faster and replace unnecessary single-use plastics at scale. We look forward to bringing Dry Molded Fiber tablet packs to life with leading brands like Bayer.”

Jesse DelGigante, Director Global Packaging Innovation at Bayer Consumer Health, said: “We have a bold commitment to transform 100% of our packaging to be recyclable or renewable by 2030 and have committed to invest €100 million investment in changing how our products are made and consumed. Achieving this will require working with the best partners and we are proud to be a part of the Blister Pack Collective as we work to make a real impact for sustainability.”

This Collective is one element of PA and PulPac’s mission to leverage Dry Molded Fiber to convert renewable plant fibers into a wide range of sustainable packaging and products. Dry Molded Fiber delivers a better environmental footprint than single use plastics at comparable speed, scalability, and cost.

As the global brand development partner for Dry Molded Fiber technology, PA works closely with renowned brands to develop tailored packaging and product solutions. In their Collective approach, they work with multiple brand partners to address global and industry-wide sustainability challenges, taking collective action to make a positive impact on the world.