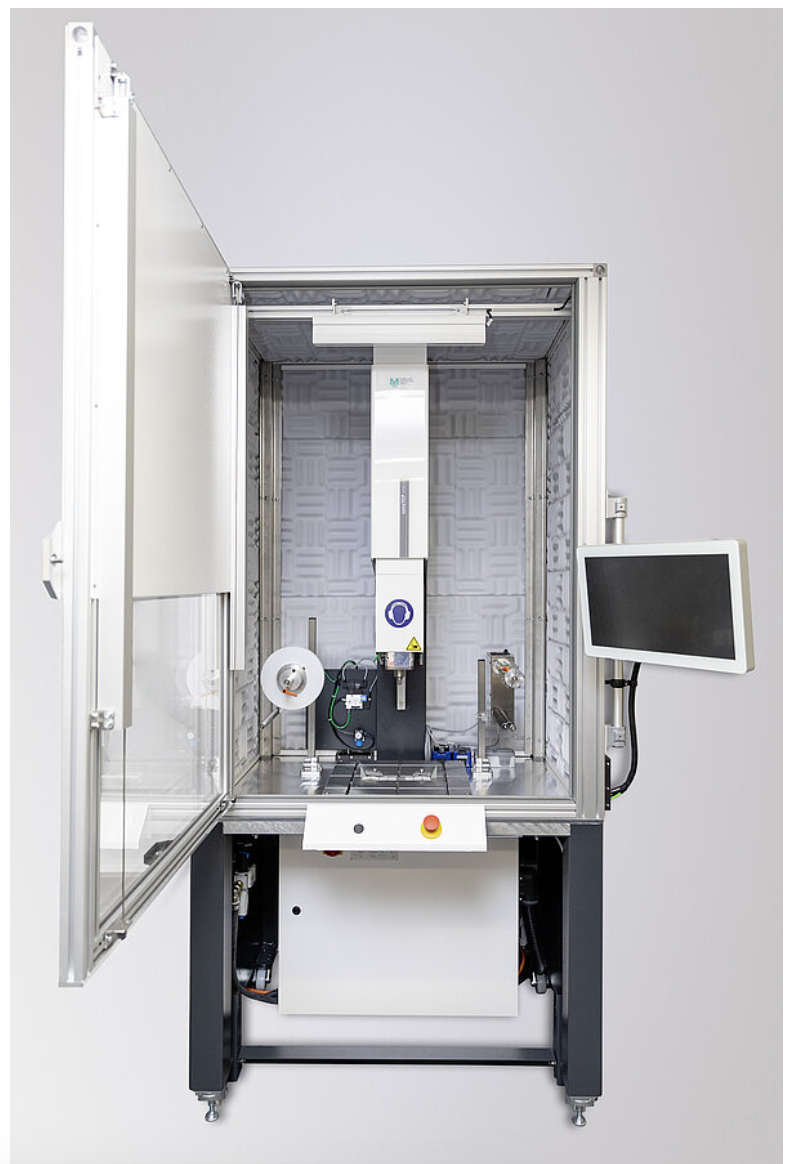

Higher speed, greater precision, better for the environment: The benefits of ultrasonic welding are obvious, and the technology has become a staple in many industrial sectors. Now, the name of the game in the industry is to make existing systems even better. The current multi-frequency machine is a case in point. The sonxTOP line of MS Ultraschall based in the Swabian region of Germany has a servo-electric drive concept that operates without compressed air, is ideally suited for clean-room environments, and ensures process and reproduction accuracy. But the machine has even more capabilities than that: The generator is the first of its kind to provide all commonly used frequencies. “Whether 20, 30, 35 or 40 kHz—with this range of ultrasonic frequencies, the MS sonxTOP with Multifrequency is a world first offering maximum flexibility that leaves nothing to be desired,” says Thomas Winker, Team Leader, Mechanical Engineering at MS. As a result, only one instead of up to four machines is required for processing.

The machine’s footprint was only one of the selling points for Schreiner ProTech’s experts. Of equal interest to them were the possibilities of torsional welding, a method that works well with thin-walled materials such as pressure compensation seals (PCS) and even enables the processing of wafer-thin ePTFE films that are stabilized by supporting non-woven material. The final products are thinner, their characteristics are not impaired by this manufacturing process, and they satisfy all the exacting requirements to be met by a PCS. “That’s high tech in torsional welding,” says Adrian Marggraf, PCS Product Manager at Schreiner ProTech. “We purchased the MS sonxTOP with Multifrequency for our in-house test laboratory because we regard it as delivering real value for our customers,” Marggraf continues. “With the new machine, all our laboratory equipment is state-of-the-art. We firmly believe that torsional ultrasonic welding represents the future in ultrasonic welding of membrane materials—and that is something we are happy to invest in.”

The development of the machine took about nine months before Schreiner ProTech is now the first customer to use the MS sonxTOP with Multifrequency. “I am proud,” says Sebastian Kirchner, Regional Sales, Series Machines, Bavaria at MS,” that in Schreiner Group we have a highly reliable partner who has confidence in MS’s technology and has recognized its significant benefits. Based on that, I am convinced that we are going to jointly continue implementing many other successful projects as part of our partnership.” The two companies are already planning their next step: later this year, a die-cutting-sealing module is supposed to be integrated into the machine as an additional feature.