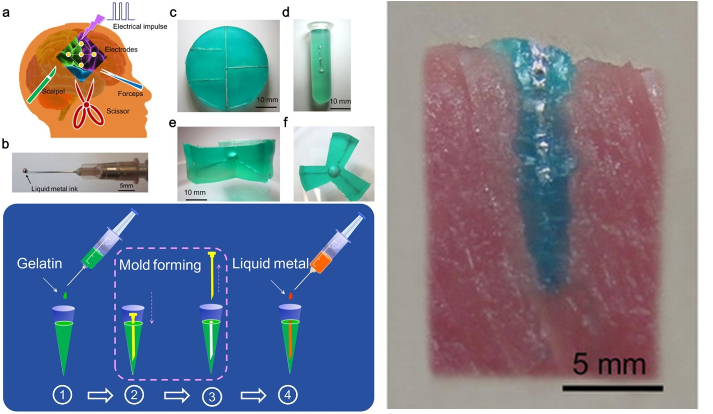

Researchers at TsingHua University in China presented an alternative way of transplantable biomedical devices by directly printing three-dimensional (3D) medical electronics inside the biological body through sequential injections of biocompatible packaging material and conductive liquid metal ink. All the complex 3-D electronics is fabricated by using the clinical syringe as the injection tool. Firstly,a 10 ml syringe with 5 ml packaging material solution (mass fraction of 25.0%) is filled and then vertically inject the solution into the target region at a rate of 1 ml/s. After removing the syringe, the syringe needle along the injection direction to shape a mold of electrode is inserted . About 3 ~ 5 min later, slowly the syringe needle is removed and a three-dimensional packaging domain would be formed. Next, a 5 ml syringe with 2 ml GaInSn-based liquid metal ink is filled and injected the ink into the electrode mold at a rate of 0.5 ml/s. Ultimately, an injected electrode can be fabricated. Using clinical syringe as the injection tool for fabricating complex 3-D object is the basic step of the present method.