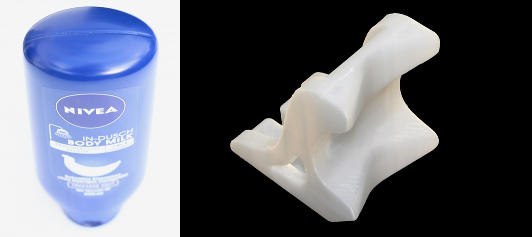

For German design engineering company ReitlingerEngineering one of the hardest parts of developing their line of automatic labeling machines was creating the clasping mechanism that allows the labels to be placed correctly. Their labeling machine was designed to hold bottles and retail packaging firmly in place while the label was applied. In order to do this the machines use a set of customized aligning jaws the exact size and shape of the packaging to clasp around it and hold it perfectly in place. This made sure that the label would be applied in the same exact spot each and every time. While the machine itself rapidly speeds up their customer’s production line, for ReitlingerEngineering and their customers developing the custom aligning jaws was a tedious, pricey and time-consuming process. In order for the aligning jaws to hold each retail package in place, ReitlingerEngineering needs to know the exact dimensions of the specific bottle or package that will be labeled. Unfortunately many of their customers often couldn’t supply an accurate 3D CAD model of the packaging, so designers at ReitlingerEngineering would need to hand measure the packaging and then manually generate a CAD model.

Once they had a 3D model, a CNC mill would be used to manufacture the front of the aligning jaws from a smooth plastic material. The new milled part would then need to be fit to an aluminum universal holder that would connect the jaws to the labelling machine. Not only was producing new aligning jaws costly to their customers, but it often slowed down the production time when one of them needed to be replaced or the company wanted to update their packaging.

Looking to reduce the cost of the machine and the time it took to manufacture new aligning jaws, ReitlingerEngineering used 3D scanning and 3D printing technology to come up with another solution. Their new process dramatically reduced the time required to produce new aligning jaws, and also cut the cost of designing new or replacement parts. Rather than try and get potentially incorrect packaging measurements from their customers or painstakingly design a CAD model from scratch, they turned to a powerful industrial 3D scanner which captured the packaging and converted it into a 3D model. ReitlingerEngineering used a David SLS-2 3D scanner to 3D scan the package which is easily and quickly be converted into a CAD model. Once they have a CAD model a new custom aligning jaw component is designed and turned into a 3D printable file that is then printed using a German RepRap X350 3D printer. The new process allowed ReitlingerEngineering to not only reduce cost and production time, but they were able to redesign the entire clasp itself. The new design completely eliminates the need for the aluminum support structures that would hold the plastic parts in place and instead turns it into a single part that can attach directly to the machine. This new all plastic part reduces the weight of the aligning jaws by nearly 70%. Not only does this dramatic reduction in weight speed the machine up and increase production cycles, but it puts less wear and tear on the labeling machine. Because the new aligning jaw is made from a 3D scan of the actual packaging the parts fit even more snuggly than the old parts which often required the need to adjust a set of tightening screws on the aligning jaw. Now ReitlingerEngineering is capable of producing new aligning jaws within a matter of days for a total production time reduction of 25% to 40% percent depending on the geometry of the product packaging.