In 2014 GKS introduced the unique fully modular construction method of its CP and UP packaging machine series. All well-known and proven advantages of this innovative modularity are now implemented into MINI, the successor to the MP150.

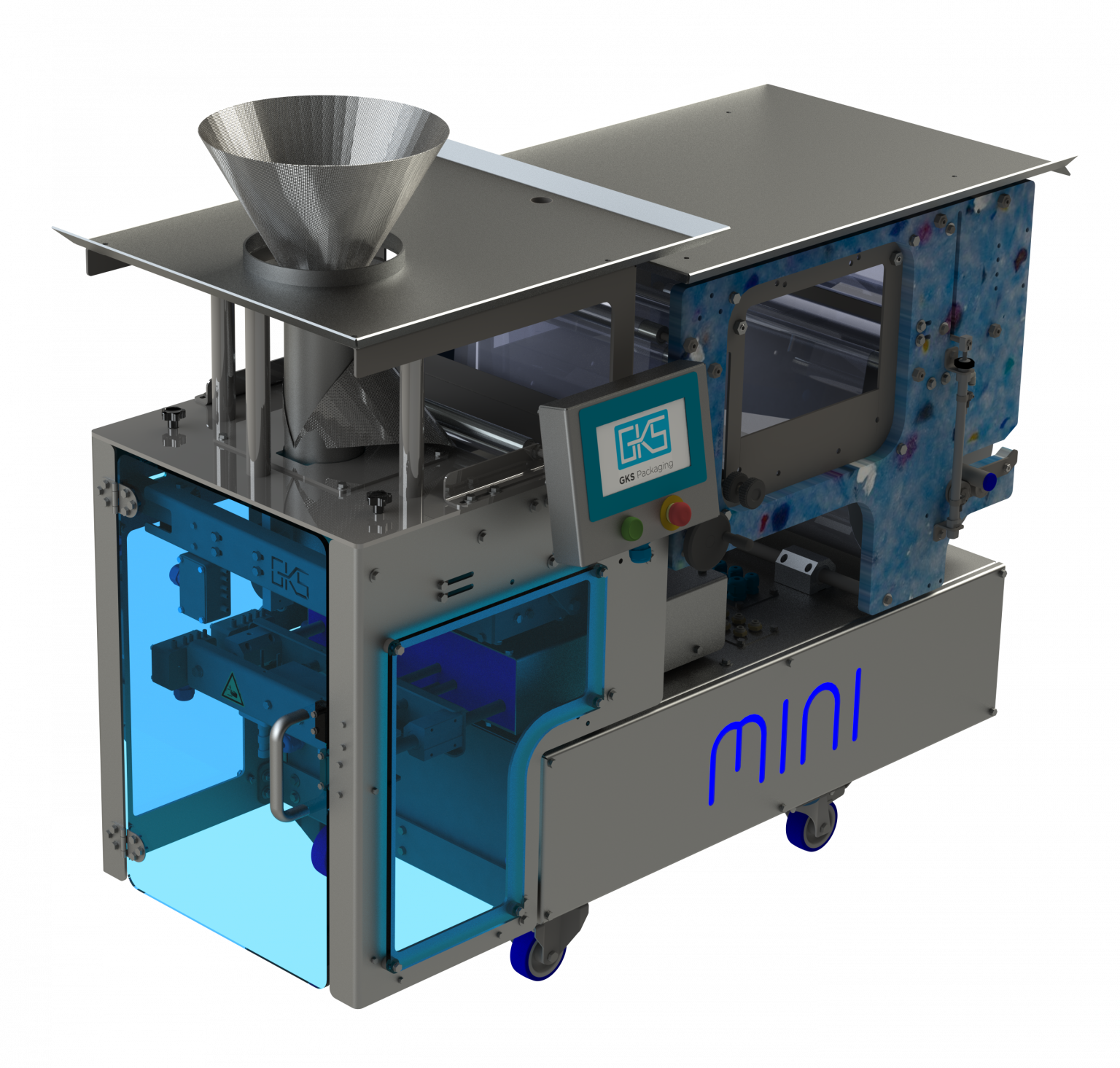

With MINI, GKS once again offers an extremely compact and competitive packaging machine, built according its inventive simplicity and characterized by a ‘frameless design’.

Despite its small dimensions, MINI is a ‘mature’ machine with a capacity of up to 65 packs per minute and a maximum bag width of 160mm.

MINI is equipped as standard with a heat sealing system for PP/laminate/paper-material, lateral film adjustment, a 7” full color touchscreen, end of film detection and servo controlled film transport.

The design of this ‘frameless’ machine also takes into account the CO2 footprint and the environment. For example the side frames are made entirely of recycled ocean plastic.

Like all other GKS machines, MINI can be equipped with many options. Such as a sealing system for PE film, MAP packing, easy opening with pouring opening, block bottom mechanism, photocell for pre-printed film and thermal transfer printer.

Also several types of dosing systems can be placed above MINI, such as a weigher, pump or auger filler. Due to its low construction height, MINI is also very suitable for manual filling.

Applications for MINI are numerous, such as packing small portions of dressing and sauces, cheese, croutons or nuts.

The first MINI’s have recently been installed and the first production series are now rolling off the factory floor.