Vision Artificial SRL Transforms Food Industry with Advanced Machine Vision and Deep Learning Solutions

Based in Bione, northern Italy, Vision Artificial SRL is making significant strides in machine vision technology, leveraging over two decades of expertise to develop automated robotic systems for various industrial sectors. The company excels in creating cutting-edge solutions that span from quality control and precise measurement systems to 3D vision, bin picking, and deep learning-powered applications.

A Game-Changer for the Food Industry: Automating Traceability of CO₂ Bottles

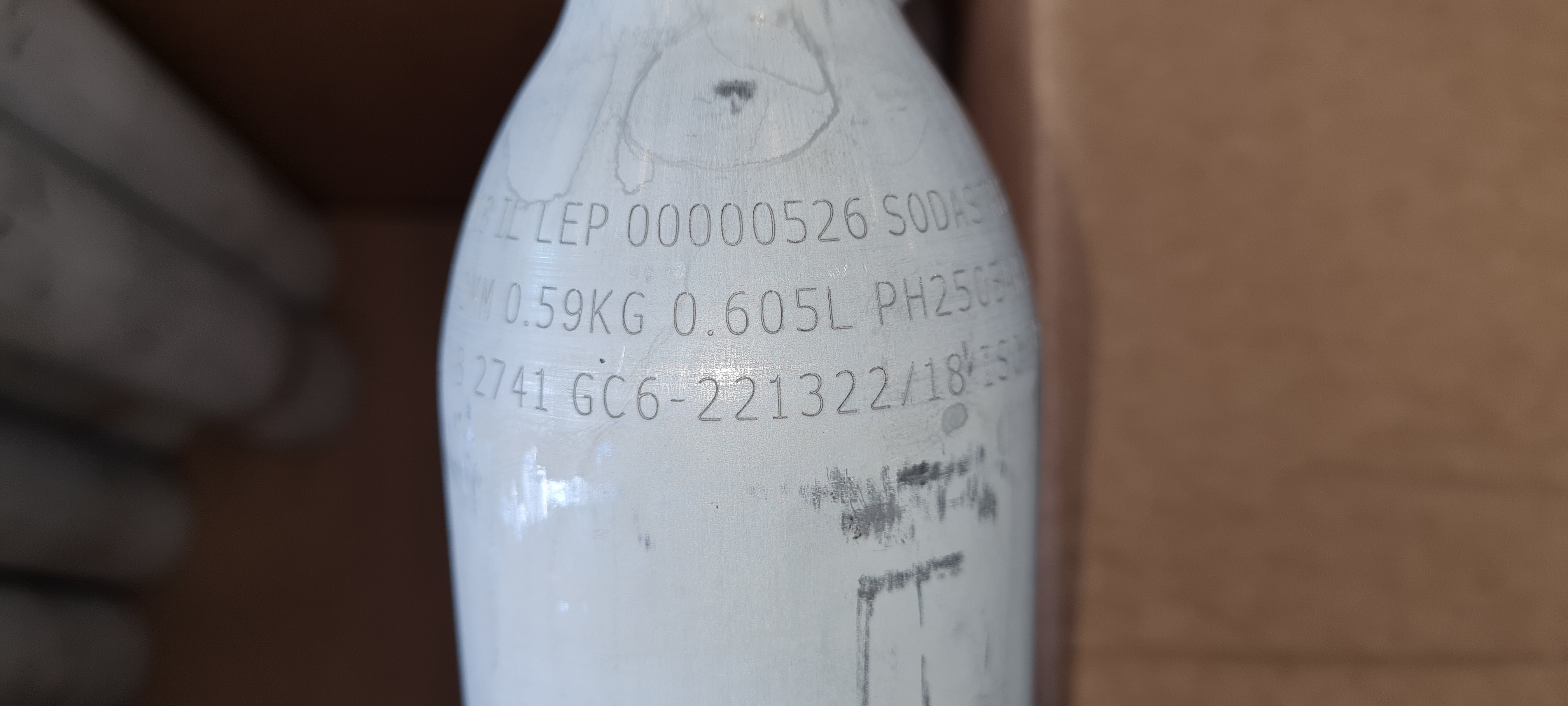

In a recent innovative project for the food industry, Visione Artificiale developed a state-of-the-art solution to automate the tracking of CO₂-filled aluminum bottles, which are used to carbonate still water. Each bottle is laser-engraved with key information, such as serial numbers, product details, bottling dates, and logos. This data allows for precise identification through optical character recognition (OCR), a critical step in maintaining efficient production and ensuring the quality of the bottles.

However, working with aluminum posed a challenge. Its reflective surfaces and potential for smudging made it difficult to capture and recognize the engraved text accurately. To solve this issue, Vision Artificial turned to MVTec HALCON's Deep OCR technology, an advanced software powered by deep learning algorithms designed to tackle these complex recognition problems.

Deep OCR: The Key to Accurate Character Recognition

Developed by Munich-based MVTec Software GmbH, HALCON’s Deep OCR proved to be the ideal solution. This powerful tool can detect and read characters, regardless of orientation, font, or polarity, and can even group letters to recognize entire words. By minimizing the misinterpretation of similar-looking characters, Deep OCR delivered a substantial improvement in recognition accuracy.

Fazio Saverio, founder of Visione Artificiale, noted the importance of this technology: "Given the reflective nature of the material, a standard OCR system would not have been sufficient for accurate identification. Deep OCR offered the intelligent solution we needed, enabling robust recognition even in challenging conditions."

The Process: Automation at Its Finest

To execute the system, aluminum bottles are secured in rotating spindles, allowing a line scan camera to capture two-dimensional images of their curved surfaces. The system then identifies text areas in the image using a confidence score to ensure precise character recognition. With two cameras and rotating devices working simultaneously, the system processes two bottles at once, significantly boosting efficiency.

With guidance from iMAGE S, a company specializing in industrial image processing solutions, Visione Artificiale successfully implemented this high-precision system, achieving faster and more reliable operations.

Results: Increased Efficiency and Enhanced Product Quality

Automating the inspection and verification of the engraved text on bottles has eliminated the need for time-consuming manual checks, freeing up employees for more critical tasks. This automation has not only improved the speed of production but has also ensured greater accuracy in traceability, ultimately enhancing the overall quality of the process.

Thanks to HALCON's Deep OCR, Vision Artificial has delivered a solution that boosts productivity, enhances product traceability, and sets a new benchmark for machine vision technologies in the food industry.

By driving these innovations, Vision Artificial SRL continues to push the limits of what can be achieved with machine vision, solidifying its leadership in the world of industrial automation.