Endless sustainable materials and pack styles continue to appease the market and challenge automation simultaneously. Brillopak, a leading UK end-of-line retail case loading specialist, will debut the multi-material handling capabilities of its new high-speed Tray & Punnet PAKer. The machine automatically packs trays and punnets into retail cases neatly and is ready for any material trend – now and in the future.

Designed to help companies keep pace with the increasing output of modern food and beverage production lines, while also adapting and transitioning from plastic to cardboard punnet packaging, Brillopak’s Tray & Punnet PAKer is the result of three years of research and development, extensive in-house expertise and deep domain expertise.

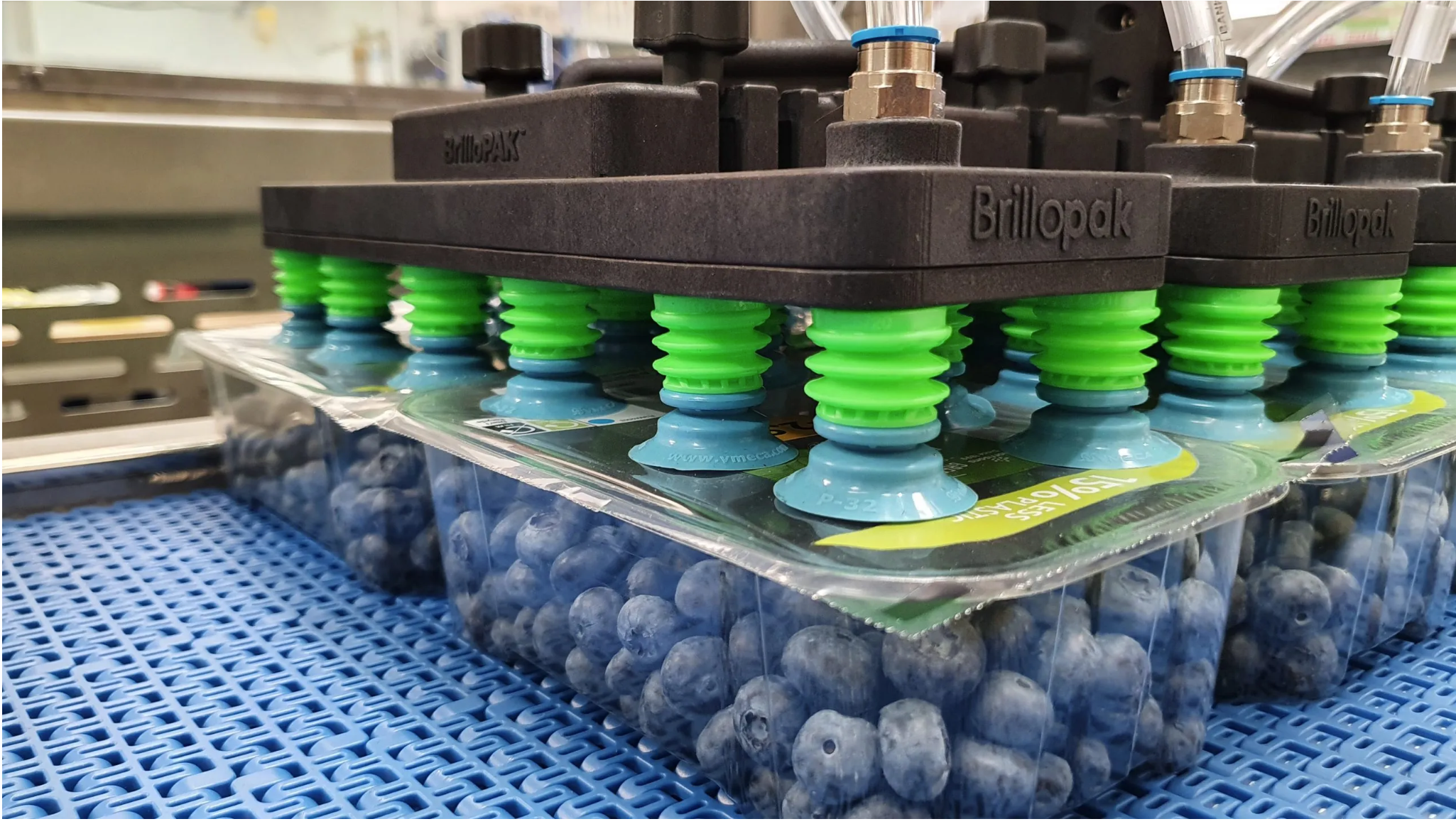

The 150-punnets-per-minute machine combines specialist robotics with patented servo-driven end effectors and then deploys them in a pick-and-place operation that seamlessly addresses many of the challenges companies face when automating this traditionally manual process

“As well as dealing with the pliability of the thin plastic punnets, customers have asked us to cater for cardboard variants too, both of which they want to be packed at speed and in neat-ly presented configurations,” explains Peter Newman, Technical Director at Brillopak.

“Dealing with any of these features in isolation is hard enough,” Newman continues, “but when you’re challenged with addressing all of them, simultaneously, it becomes much more… interesting. Fortunately, we have some superb engineers here and we were more than up to the task.”

To deliver greater speed, while still maintaining control of the pack, one robot accurately picks and places trays into a layer formation. A second robot then closes them up into an array dimension, before picking an entire layer of punnets that fits neatly into the receiving plastic/cardboard case.

This whole-layer approach also addresses misalignment issues created by single-punnet pick and place and delivers a neat retailer-ready appearance. Different packaging materials are handled equally well on the same machine using tailored packaging recipes and package-specific end effectors. In this way, packs with new, environmentally sound packaging, which can be a tight fit in a container, can still be handled consistently.

“The primary driver behind the machine’s development was from our customers,” explains David Jahn, sales director at Brillopak. “We were regularly being told ‘I need a solution to overcome the struggle of constantly trying to find new operators’. Automation was always going to be the answer, but it needs to deliver far more than just the ability to replace line-side personnel.

“In this market efficiency is everything,” he adds. “The prices are set by the supermarkets, so our customers have to find economies in all the steps prior to final delivery. This machine is more than capable of meeting current demands and deploys a technological solution that will enable users to support what they don’t know will happen tomorrow!”

.