- Hydrogen powered furnace will create the world’s first net zero glass bottles at scale

- The new ultra-low carbon hybrid glass furnace in Elton, Cheshire, to begin glass production in 2027

- By 2030, the aim is for the furnace to produce up to 200 million net zero bottles of Smirnoff, Captain Morgan, Gordon’s and Tanqueray per year

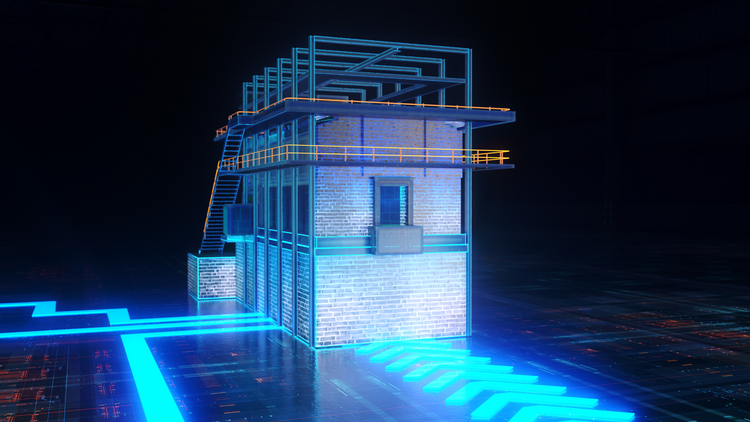

Encirc, a Vidrala company, plans to build a new furnace at its Elton plant, Cheshire, which will change the face of glass. The furnace will:

- Reduce carbon emissions by 90%, with an energy mix of green electricity and low carbon hydrogen. It is expected that carbon capture technology will capture the remaining carbon emissions by 2030

- Be powered by zero carbon electricity and hydrogen, from the Vertex (HyNet)plant in Cheshire

- Be fully operational by 2027

- Produce up to 200 million Smirnoff, Captain Morgan, Gordon’s and Tanqueray bottles annually by 2030

Encirc is already a leader in sustainable glass production and future-proofing the future of glass. In 2021, Encirc, in collaboration with glass industry partners ‘Glass Futures’, trialled one of its furnaces in its Northern Ireland plant on sustainable biofuels on many brands including Diageo’s Black & White bottles, using 100% recycled glass to create the most sustainable bottles ever produced. The bottles had a carbon footprint of up to 90% lower than a standard glass bottle.

Decarbonising glass packaging will be a key part of the UK government’s commitment to reach net zero by 2050 and this is an example of UK leading companies partnering to be innovative in using green energy to manufacture at scale. The hydrogen used to power the new furnace will come from Vertex Hydrogen, a partner of the government-backed HyNet North West cluster – the UK’s leading industrial decarbonisation project.

Glass Futures, based in St Helens, is also playing a key role in supporting the glass industry’s decarbonisation and is a key partner for Encirc. It will be instrumental in trialling sustainable fuels on

furnaces and developing the future furnace technology required to support Encirc and the wider glass industry in its goals.

Adrian Curry, Managing Director of Encirc said: “This will be a major step in our goal of producing net zero glass by 2030. With support from the Government and key partners, Encirc and Diageo we believe it will be possible to have this first of its kind furnace up and running at the beginning of 2027.

“Glass is an incredible material being infinitely recyclable and chemically inert. It has been around since 3500 BC and has never been produced in this way. This is about protecting glass as a material by addressing the carbon challenge. The work we and Glass Futures undertake will be shared with the UK glass industry to ensure glass remains as the packing of choice for many thousands more years!”

Low-carbon alternative energy sources are an essential part of the solution for net zero. Hydrogen has the potential to be a crucial clean energy source for businesses and industries across the UK and global economies.

Commenting, Ewan Andrew, President, Global Supply & Procurement and Chief Sustainability Officer at Diageo, said: “We are really excited to be a part of this world leading announcement which forms part of our commitment to halve our Scope 3 carbon emissions by 2030. All renewable energy options are important to us and we’d like to see Government and industry further accelerating the direct supply of green energy as a mainstream option. Ultimately, we look forward to a world where people can enjoy their favourite drinks from zero carbon glass bottles.”

Joe Seifert, CEO of Vertex Hydrogen, said: “We are delighted to be supporting Encirc and Diageo with low carbon hydrogen as the UK continues to lead the world to deliver tangible decarbonisation at pace and scale.”

The use of the zero-carbon furnace will contribute towards Diageo’s commitments in its ESG action plan Society 2030 to reduce carbon emissions across its supply chain by 2030.