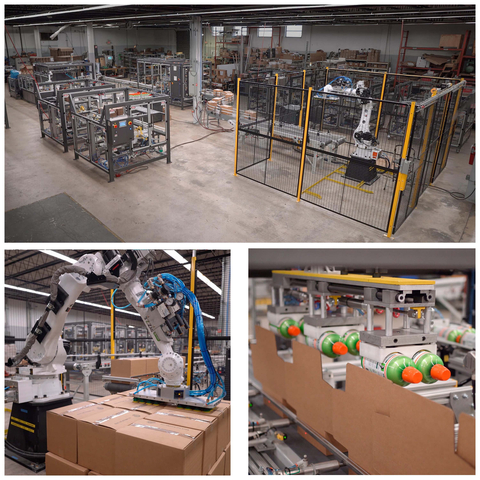

EndFlex announced the completion of a highly customized end-of-line system in an astonishing 20 weeks. Engineered for its client in the personal hygiene market, this fully automated system conveys bottled product into the Traypacker™ modular pick & place cell where it is packed into a tray that is fully formed and sealed by dual Poplok® tray formers. In the final stages, the Boxxer™ all-in-one system forms, packs and seals the loaded trays into cases before conveying them to the Z.Zag™ robotic palletizer where the cases are precisely stacked for shipping.

This complex, integrated system was engineered to accommodate the client’s unique bottle shape, existing tray and case dimensions and strict daily production goal. These factors necessitated the use of features such as simultaneous tray forming, a custom bottle infeed and tipping process with redesigned pick & place functionality and specialized programming that allows the robotic palletizer to both stack outgoing cases onto pallets and remove incoming cases from pallets when needed.

“The combination of so many unique features in this packaging line presented a complex challenge, but we are used to completing custom projects after the client was told by other vendors that it couldn’t be done. Not only did our design and fabrication teams complete this project flawlessly, but the client was absolutely blown away by turnaround time and the precise functionality,” said Jorge Perez, Vice President of Operations at EndFlex. “The client is now able to dramatically increase production and delivery capacity. We anticipate this system design will be popular this year as companies look to decrease labor costs.”

EndFlex can customize end-of-line solutions to meet almost any production need. Their case erecting, tray forming, case packing and palletizing solutions can seamlessly integrate with other machines in the EndFlex family including horizontal and vertical cartoning machines, case sealing machines and a variety of carton and case labelers.