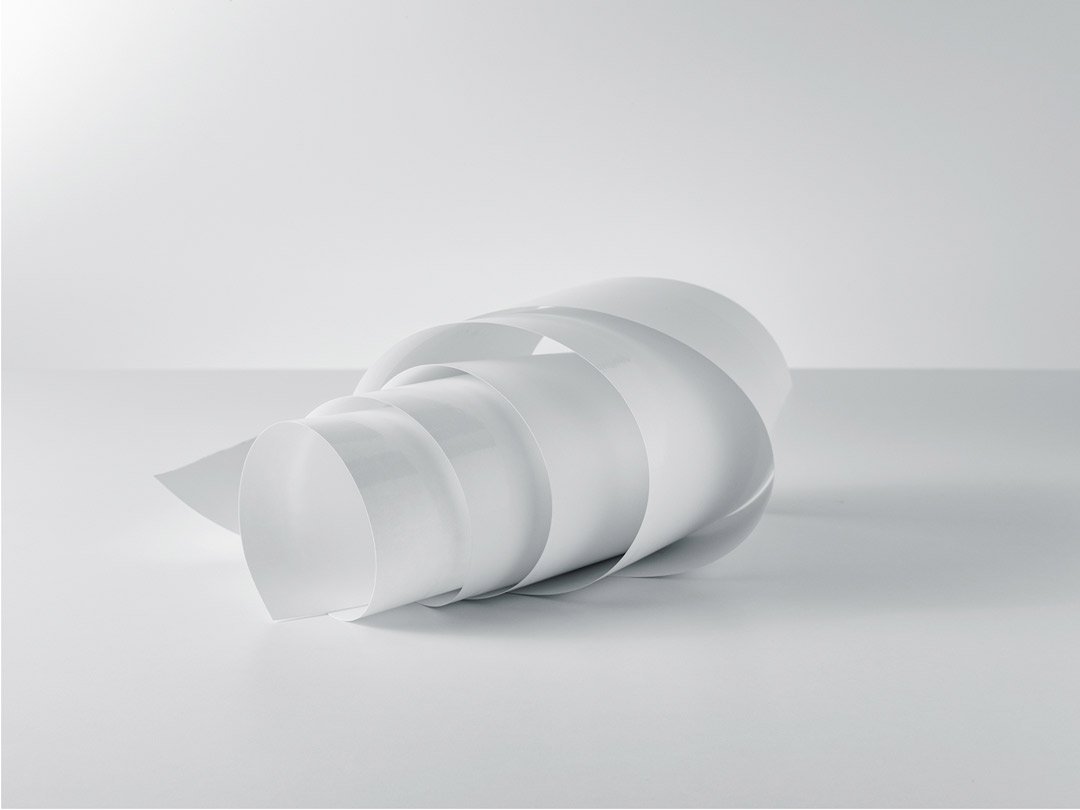

The new laminate is considered to be “one-sided”, which the company reports has been requested by many brand owners and retailers. The product is based on stretchable and printable paper-based laminates that can be shaped, twisted and embossed.

Up until now, FreeForm Packaging has only been able to offer laminates with polythene on both sides to ensure good sealing properties, but this has now changed.

A new process enables the packages to be fully sealed and makes it possible to shape them as required. The new laminate still reportedly offers good water vapor transmission rate (WVTR) values, although the company admits that it is less effective than a double-sided laminate.

Danevert Åsbrink, CEO of FreeForm Packaging AB, comments: “The new laminate allows the FreeFormPack system to produce formable paper packaging that is pleasant to the touch, which customers have been wanting for a very long time. We have been working hard on this for the last six years, so it feels almost unreal to have finally reached our goal.”

The FreeFormPack ‘Standard Paper Out’ laminate has two layers of FibreForm, and one of its two sides has a thin layer of polyethylene that protects the contents while also protecting the packaging.