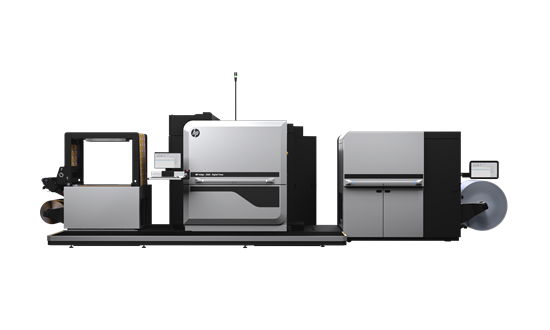

The new Series 5 HP Indigo 200K digital press prints up to 56 m/min (183 ft/min) designed to increase the productivity of high-margin, sustainable short runs of digital flexible packaging, to be delivered in days.

HP said the Indigo 200K digital press and is food packaging compliant, and achieves ves a 30% increase in speed and 45% boost in productivity compared to the HP Indigo 25K.

It is designed to help digital flexible converters increase productivity, on-demand delivery, no minimum orders, as well as reduced energy consumption, and minimal waste.

Featuring gravure-matching color quality based on the HP Indigo Liquid Electro Photography (LEP) and One-Shot Color technologies, the new press offers the widest available range of ElectroInks and is designed to print high coverage packages with white on the majority of industrial substrates, both surface and reverse.

“The HP Indigo 200K is a mid-web digital press especially designed for converters addressing the needs of brands in flexible packaging, but it also serves the growing requirements of the label and shrink sleeve industries for higher productivity and wider format,” said Noam Zilbershtain, VP & general manager of HP Indigo & Scitex.

“Flexible Packaging is a growing market, and as HP Indigo customers are growing much faster than the market , I have no doubt that the HP Indigo 200K digital press will open the door for more flexo converters who want to join the success, and reign in industry 4.0.”

Midlands-based Sirane Group is one of the press’ first beta customers, Peter Ralten, commercial and business development director said: “At Sirane, we have been looking into digital print for a while now, realizing it is where the future lies. The HP Indigo 200K digital press, with its incredible increase in productivity, opens new business opportunities for us. With the unmatched HP Indigo quality and versatility, we can’t wait to see the results of adding it to our portfolio.”