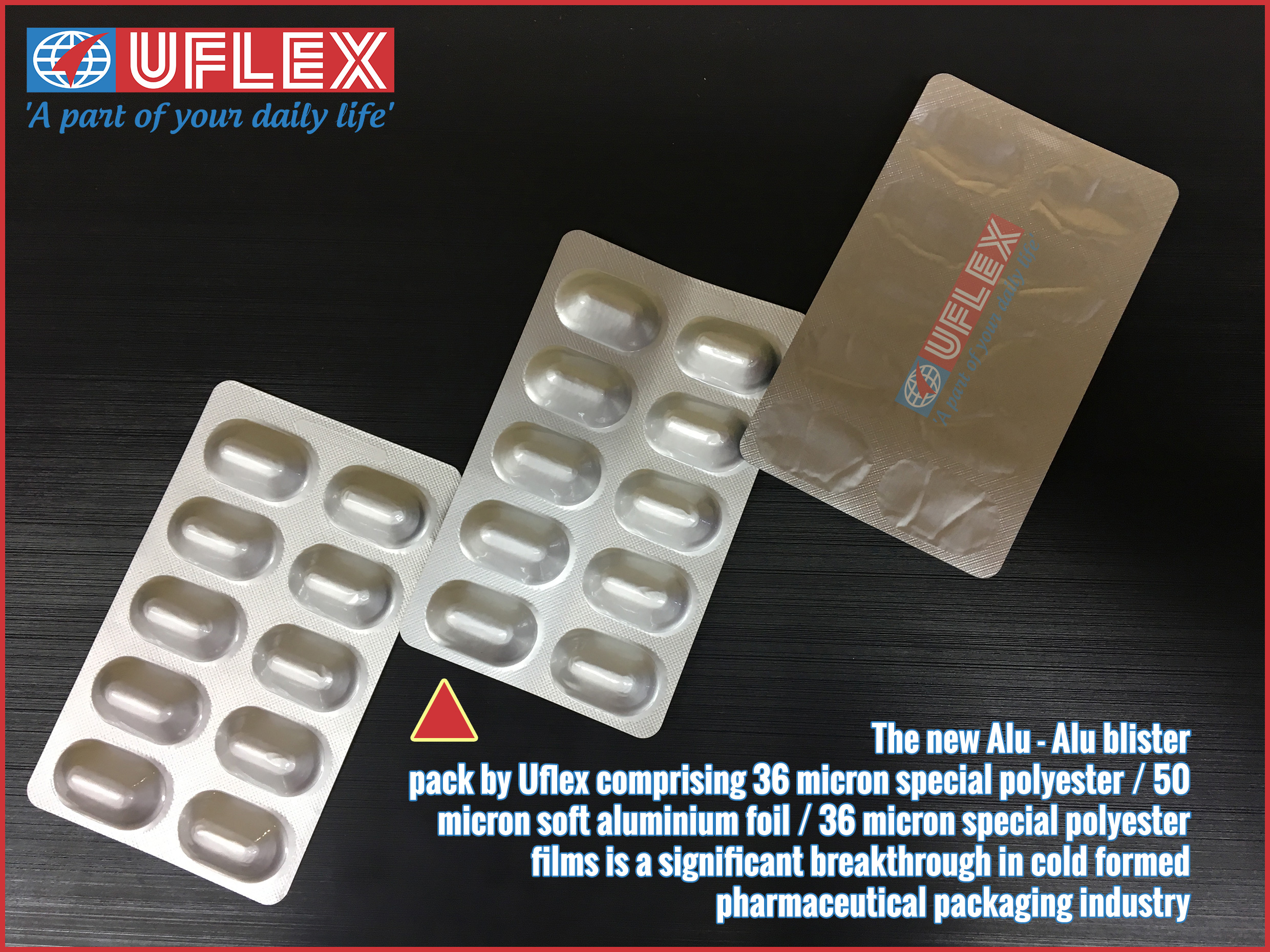

Eliminating BOPA and PVC films in the cold formed Alu- Alu laminate blister pack in pharmaceuticals remains a difficult task till now. A conventional cold formed pharmaceutical blister back when dumped in the land fill gives away chlorine upon coming in contact with sunlight. This is extremely harmful for the environment. PVC also contains plasticizers with phthalates linked to a host of health disorders that can damage the liver, kidneys, lungs and reproductive system. PVC film leaves high carbon footprint making it further undesirable from the environmental perspective besides exhibiting very low temperature resistance which is yet another shortcoming. BOPA (BON) on the other hand is also fraught with challenges like high moisture absorption to the tune of 8-10% making its processing difficult; leading to de-lamination and impairing the ability of the film to be chemically primed. Uflex has developed a special polyester film that obviates the problems posed by BON and PVC. The special polyester film is all set to replace the top and bottom substrates of the conventional cold formed Alu – Alu laminate to a whole new structure comprising 36 micron special polyester/ 50 micron soft aluminium foil/ 36 micron special polyester. Polyester is a para-crystalline material which possesses excellent barrier, clarity, printability, and hardness properties. Film forming and orientation of polyester augurs well for the creation of thin profile webs with excellent properties for use in flexible packaging. This speciality film that has been developed by Uflex can be laminated on both sides of the aluminium foil without any problem quite like the laminate comprising BOPA, Aluminium Foil and PVC films. The engineers at Films Business of Uflex have been successfully able to bring metaphase morphology which has made it possible to form the film in Z direction which happens to be a pre-requisitefor blister packaging.